4.2.1 Installation environment

The installation environment is the safeguard for the full play and long-term stable function of the VFD. Check the installation environment as followings:

Environment | Conditions |

Installation site | Indoor |

Environment temperature | -10–+50°C If the ambient temperature of the VFD is above 40°C, derate 1% for every additional 1°C. It is not recommended to use the VFD if the ambient temperature is above 50°C. In order to improve the reliability of the device, do not use the VFD if the ambient temperature changes frequently. Please provide cooling fan or air conditioner to control the internal ambient temperature below the required one if the VFD is used in a close space such as in the control cabinet. When the temperature is too low, if the VFD needs to restart to run after a long stop, it is necessary to provide an external heating device to increase the internal temperature, otherwise damage to the devices may occur. |

Humidity | RH≤90% No condensation is allowed. The maximum relative humility should be equal to or less than 60% in corrosive air. |

Storage temperature | -30–+60°C |

Running environment condition | The installation site of the VFD should: keep away from the electromagnetic radiation source; keep away from contaminative air, such as corrosive gas, oil mist and flammable gas; ensure foreign objects, such as metal power, dust, oil, water cannot enter into the VFD (do not install the VFD on the flammable materials such as wood); keep away from direct sunlight, oil mist, steam and vibration environment. |

Altitude | When the altitude exceeds 1000m but is lower than 3000m, derate 1% for every additional 100m; When the altitude exceeds 2000m, configure an isolation transformer on the input end of the VFD. When the altitude exceeds 3000m but is lower than 5000m, contact us for technical consultation. Do not use the VFD at an altitude higher than 5000m. |

Vibration | ≤ 5.88m/s2 (0.6g) |

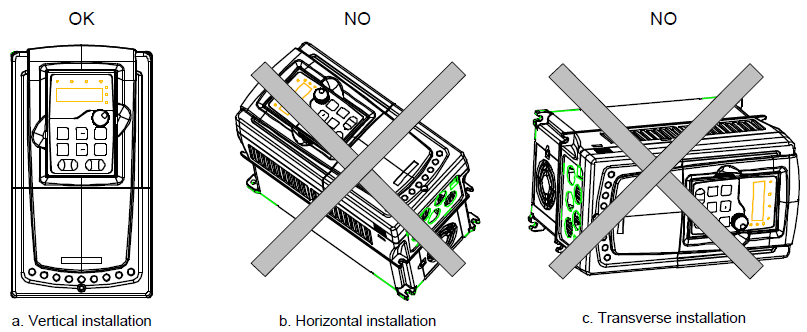

Installation direction | The VFD should be installed upright to ensure the cooling effect. |

Note:

Goodrive300 series VFDs should be installed in a clean and ventilated environment according to enclosure classification.

Cooling air must be clean without corrosive gas or electrically conductive dust.

4.2.2 Installation direction

The VFD may be installed on the wall or in a cabinet.

The VFD must be installed upright. Check the installation site according to the requirements below. Refer to chapter Dimension Drawings in the appendix for frame details.

Figure 4-1 Installation direction of the VFD

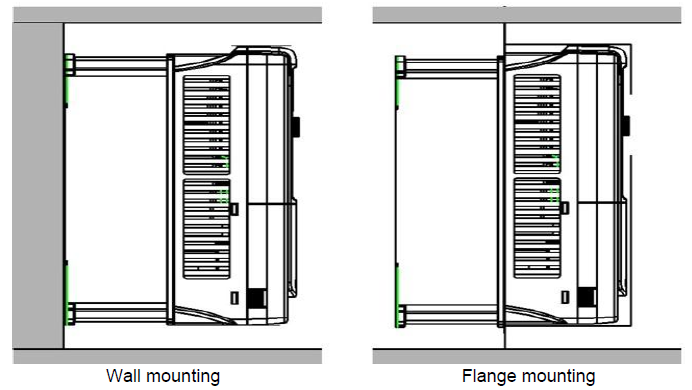

4.2.3 Installation mode

The VFD can be installed in three different ways, depending on the frame size:

a) Wall mounting, applicable for VFDs of 380V (≤315kW), 500V (≤75kW), and 660V (≤350kW)

b) Flange mounting, applicable for VFDs of 380V (≤200kW), 500V (≤75kW), and 660V (≤200kW)

c) Floor mounting, applicable for VFDs of 380V (220–500kW) and 660V (250–630kW)

Figure 4-2 Installation mode

(1) Mark the hole location. The location of the holes is shown in the dimension drawings in the appendix.

(2) Fix the screws or bolts to the marked locations.

(3) Put the VFD against the wall.

(4) Tighten the screws in the wall securely.

Note:

The flange installation of the VFDs of 380V 1.5–30kW and 500V 4–18.5kW need flange board, while the flange installation of the VFDs of 380V 37–200kW, the flange installation of the VFDs of 500V 22–75kW and 660V 22–220kW does not need.

The installation of the VFDs of 380V 220–315kW and 660V 250–350kW need optional bases which need an input AC reactor (or DC reactor) and output AC reactor.

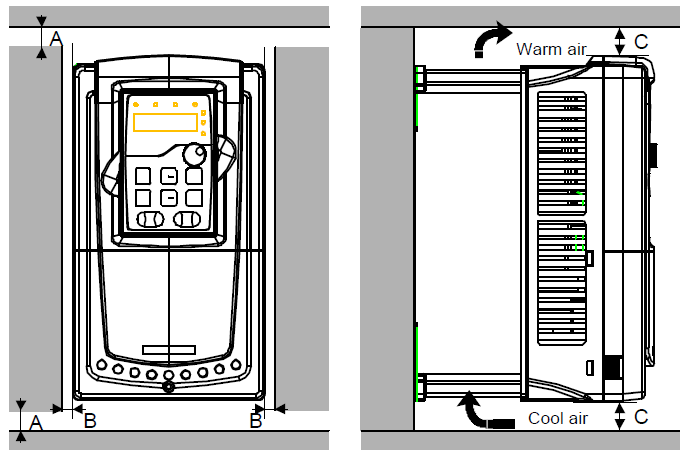

4.2.4 Installation of one VFD

Figure 4-3 Stand-alone installation

Note: The minimum space of B and C is 100 mm.

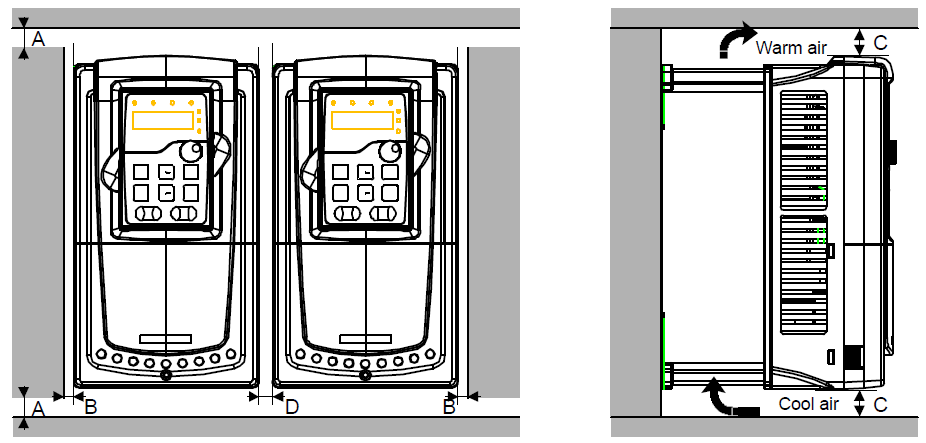

4.2.5 Installation of multiple VFDs

Figure 4-4 Parallel installation

Note:

Before installing the different sizes VFDs, please align their top position for the convenience of later maintenance.

The minimum space of B, D and C is 100 mm.

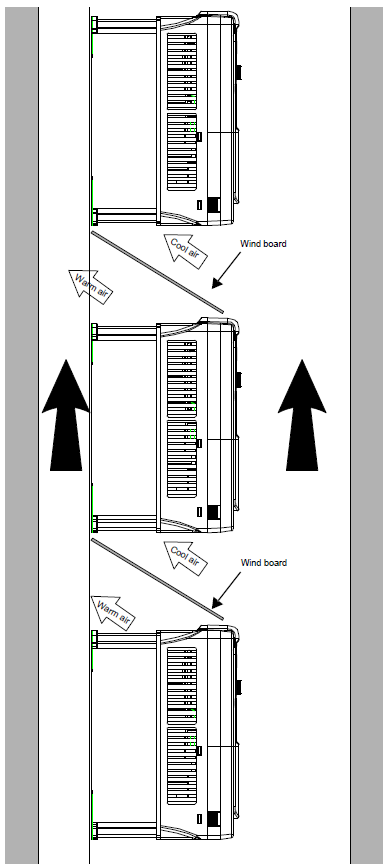

4.2.6 Vertical installation

Figure 4-5 Vertical installation

Note: Windscreen should be installed in vertical installation to prevent mutual impact and insufficient cooling.

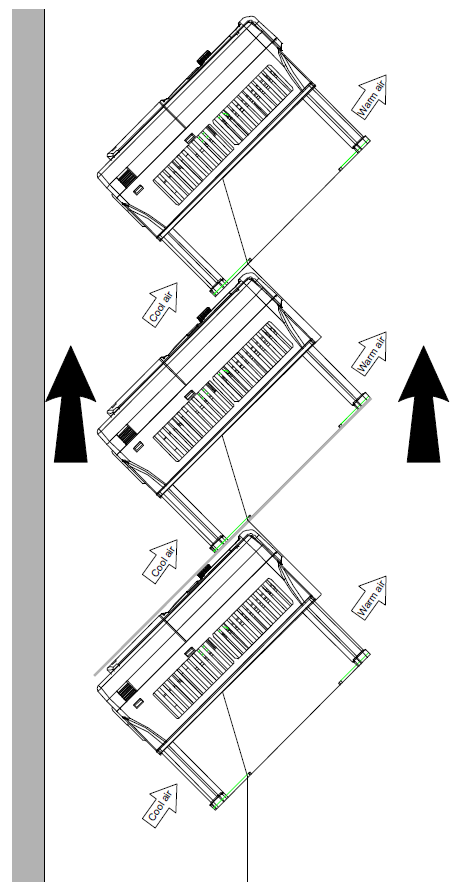

4.2.7 Tilt installation

Figure 4-6 Tilt installation

Note: Ensure the separation of the wind input and output channels in tilt installation to prevent mutual impact.