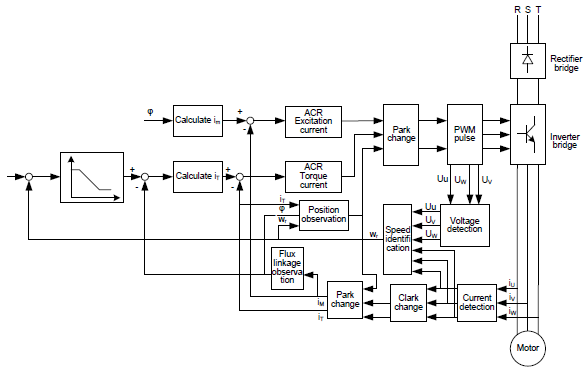

Because asynchronous motors have the characteristics of high stage, nonlinear, strong coupling and various variables, the actual control of the asynchronous motor is very difficult. Vector control is mainly used to settle this problem with the theme of that divide the stator current vector into exciting current (the current heft generating internal magnetic field of the motor) and torque current (the current heft generating torque) by controlling and measuring the stator current vector according to the principles of beamed magnetic field to control the range and phase of these two hefts. This method can realize the decoupling of exciting current and torque current to adjust the high performance of asynchronous motors.

Goodrive35 series VFDs are embedded speedless sensor vector control calculation for driving both asynchronous motors and synchronous motors. Because the core calculation of vector control is based on exact motor parameter models, the accuracy of motor parameter will impact on the performance of vector control. It is recommended to input the motor parameters and carry out autotune before vector running.

Because the vector control calculation is very complicated, high technical theory is needed for the user during internal autotune. It is recommended to use the specific function parameters in vector control with cautions.

Function code | Name | Detailed instruction of parameters | Default value |

P00.00 | Speed control mode | 0: Sensorless vector control mode 1 1: Sensorless vector control mode 2 2: SVPWM control 3: Closed-loop vector control mode | 2 |

P00.15 | Motor parameter autotuning | 0: No operation 1: Rotation autotuning 2: Static autotuning 1 (autotune totally) 3: Static autotuning 2 (autotune part parameters) | 0 |

P02.00 | Motor type 1 | 0: Asynchronous motor 1: Synchronous motor | 1 |

P03.00 | ASR proportional gain1 | 0–200.0 | 16.0 |

P03.01 | ASR integral time1 | 0.000–10.000 s | 0.200 s |

P03.02 | Low-point frequency for switching | 0.00 Hz–P03.05 | 5.00 Hz |

P03.03 | ASR proportional gain 2 | 0–200.0 | 10.0 |

P03.04 | ASR integral time 2 | 0.000–10.000 s | 0.200 s |

P03.05 | High-point frequency for switching | P03.02–P00.03 (max. output frequency) | 10.00 Hz |

P03.06 | ASR output filter | 0–8 (corresponds to 0–28/10 ms) | 0 |

P03.07 | Compensation coefficient of electromotion slip | 50%–200% | 100% |

P03.08 | Compensation coefficient of brake slip | 50%–200% | 100% |

P03.09 | ACR proportional coefficient P | 0–20000 | 1000 |

P03.10 | ACR integral coefficient I | 0–20000 | 1000 |

P03.11 | Torque setting method | 0: Torque control is invalid 1: Keypad setting torque (P03.12) 2: Analog AI1 setting torque 3: Analog AI2 setting torque 4: Analog AI3 setting torque 5: Pulse frequency HDI setting torque 6: Multi-step torque setting 7: Modbus communication setting torque 8: PROFIBUS/CANopen communication setting torque (the same as above) 9: Ethernet communication setting torque (the same as above) 10: Reserved Note: Setting modes 2–10, 100% corresponds to three times of the rated current of the motor. | 0 |

P03.12 | Keypad setting torque | -300.0%–300.0% (rated motor current) | 10.0% |

P03.13 | Torque reference filter time | 0.000–10.000s | 0.100 s |

P03.14 | Upper frequency of forward rotation in vector control | 0: Keypad (P03.16) 1: AI1 2: AI2 3: AI3 4: Pulse frequency HDI setting upper-limit frequency 5: Multi-step setting upper-limit frequency 6: Modbus communication setting upper-limit frequency 7: PROFIBUS/CANopen communication setting upper-limit frequency 8: Ethernet communication setting upper-limit frequency (the same as above) Note: Setting method 0–8, 100% corresponds to the maximum frequency. | |

P03.15 | Upper frequency of reverse rotation in vector control | 0: Keypad (P03.17) 1–8: The same as P03.14 | |

P03.16 | Keypad setting for upper frequency of forward rotation | Setting range: 0.00 Hz–P00.03 (max. output frequency) | 50.00 Hz |

P03.17 | Keypad setting for upper frequency of reverse rotation | 50.00 Hz | |

P03.18 | Upper electromotion torque source | 0: Keypad setting upper-limit frequency (P03.20) 1: AI1 2: AI2 3: AI3 4: HDI 5: Modbus communication 6: PROFIBUS/CANopen communication 7: Ethernet communication Note: Set mode 1–7, 100% corresponds to three times of the motor current. | |

P03.19 | Upper brake torque source | 0: Keypad (P03.21) 1–7: The same as P03.18 | |

P03.20 | Keypad setting of electromotion torque | 0.0–300.0% (rated current of the motor) | 180.0% |

P03.21 | Keypad setting of brake torque | 180.0% | |

P03.22 | Weakening coefficient in constant power zone | 0.01–2.00 | 1.00 |

P03.23 | Lowest weakening point in constant power zone | 5%–50% | 10% |

P03.24 | Max voltage limit | 0.0–120.0% | 100.0% |

P03.25 | Pre-exciting time | 0.000–10.000 s | 0.0 s |

P03.26 | Weak proportional gain | 0–8000 | 1200 |

P03.27 | Integral gain of the flux weakening | 0–8000 | 1200 |

P03.28 | Control mode of the flux weakening | 0x000–0x112 Ones: Control mode selection 0–2 Tens: Inductance compensation selection 0: Compensate 1: Not compensate Hundreds: High speed control mode 0: Mode 0 1: Mode 1 | 0x000 |

P03.29 | Torque control mode | 0x0000–0x7111 Ones: Torque command selection 0: Torque reference 1: Torque current reference Tens: Torque compensation direction at 0 speed 0: Positive 1: Negative Hundreds: ASR integral separation setting 0: Disabled 1: Enabled Thousands: Torque control word setting Bit0: Torque command filtering mode 0: Inertia filter 1: Linear ACC/DEC filtering Bit1–2: ACC/DEC time for rotating speed upper limit 0: No ACC/DEC time 1: ACC/DEC time 1 2: ACC/DEC time 2 3: ACC/DEC time 3 | 0x0001 |

P03.30 | Low-speed friction torque | 0–50.0% (rated torque of the motor) | 0.0% |

P03.31 | High-speed friction torque | 0–50.0% (rated torque of the motor) | 0.0% |

P03.32 | Corresponding frequency of high-speed friction torque | 1.00 Hz–400.00 Hz | 50.00 Hz |