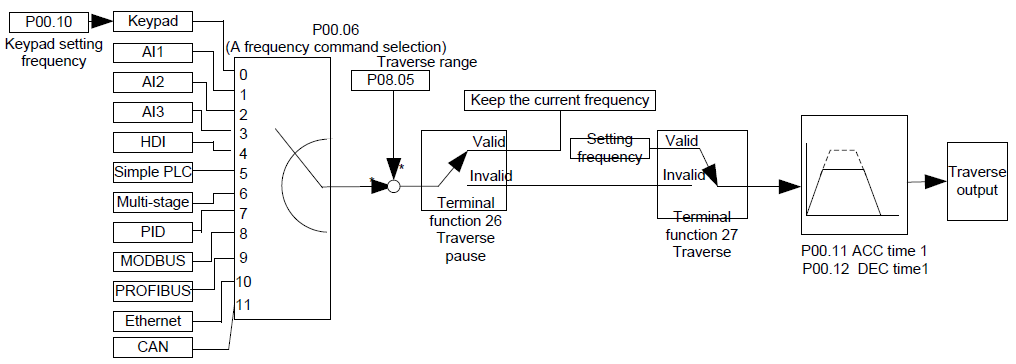

Traverse is applied in some industries such as textile, chemical fiber and cases where traverse and convolution is required. The working flowchart is as below:

Function code | Name | Detailed instruction of parameters | Default value |

P00.03 | Max. output frequency | P00.03–400.00Hz | 50.00Hz |

P00.06 | A frequency command | 0: Keypad 1: AI1 2: AI2 3: AI3 4:High-speed pulse HDI 5:Simple PLC program 6: Multi-step speed running 7: PID control setting 8: Modbus communication setting 9: PROFIBUS/CANopen communication setting 10: Ethernet communication setting(reserved) 11: Reserved | 0 |

P00.11 | ACC time 1 | 0.0–3600.0s | Depend on model |

P00.12 | DEC time 1 | 0.0–3600.0s | Depend on model |

P05.01–P05.09 | Digital input function selection | 26:Traverse Pause (stop at the current frequency) 27:Traverse reset (return to the center frequency) | |

P08.15 | Traverse range | 0.0–100.0% (corresponding to the set frequency) | 0.0% |

P08.16 | Sudden jumping frequency range | 0.0–50.0% (corresponding to the traverse range) | 0.0% |

P08.17 | Traverse boost time | 0.1–3600.0s | 5.0s |

P08.18 | Traverse declining time | 0.1–3600.0s | 5.0s |