Various operations can be performed on the VFD, including entering/exiting menu, parameter selection, list modification and parameter addition.

5.4.1 Enter/exit menu

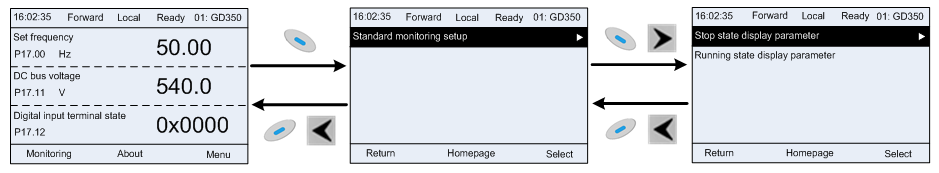

Regarding the monitoring menu, the operation relation between enter and exit is shown below.

Figure 5–8 Enter/exit menu diagram 1

Regarding the system menu, the operation relation between enter and exit is shown in the following figure.

Figure 5–9 Enter/exit menu diagram 2

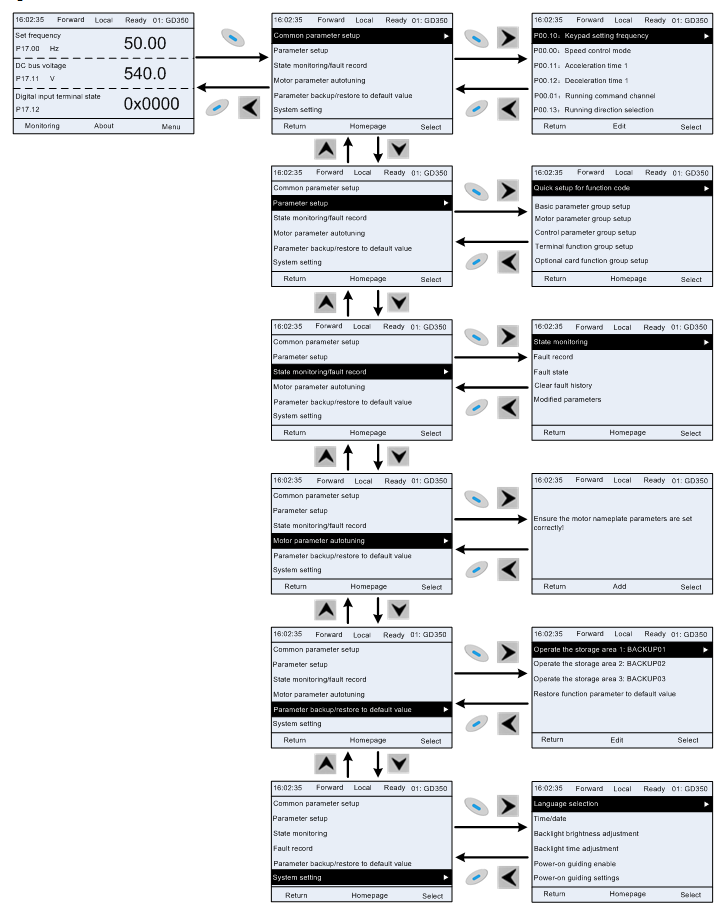

The keypad menu setup is shown as below.

First-level | Second-level | Third-level | Fourth-level |

Common parameter setup | / | / | P00.10: Set frequency via keypad |

P00.00: Speed control mode | |||

Pxx.xx : Common parameter setup xx | |||

Quick setup for function code | / | Pxx.xx | |

Parameter setup | Basic parameter group setup | P00: Basic function group | P00.xx |

P07: HMI group | P07.xx | ||

P08: Enhance function group | P08.xx | ||

P11: Protection parameter group | P11.xx | ||

P14: Serial communication function group | P14.xx | ||

P99: Factory function group | P99.xx | ||

Motor parameter group setup | P02: Motor 1 parameter group | P02.xx | |

P12: Motor 2 parameter group | P12.xx | ||

P20: Motor 1 encoder group | P20.xx | ||

P24: Motor 2 encoder group | P24.xx | ||

Control parameter group setup | P01: Start/stop control group | P01.xx | |

P03: Motor 1 vector control group | P03.xx | ||

P04: V/F control group | P04.xx | ||

P09: PID control group | P09.xx | ||

P10: Simple PLC and multi-step speed control group | P10.xx | ||

P13: Synchronous motor control parameter group | P13.xx | ||

P21: Position control group | P21.xx | ||

P22: Spindle positioning group | P22.xx | ||

P23: Motor 2 vector control group | P23.xx | ||

Terminal function group setup | P05: Input terminal group | P05.xx | |

P06: Output terminal group | P06.xx | ||

P98: AIAO calibration function group | P98.xx | ||

Optional card function group setup | P15: Communication extension card 1 function group | P15.xx | |

P16: Communication extension card 2 function group | P16.xx | ||

P25: Extension I/O card input function group | P25.xx | ||

P26: Extension I/O card output function group | P26.xx | ||

P27: PLC function group | P27.xx | ||

P28: Master/slave function group | P28.xx | ||

Default function group setup | P90: Customized function group 1 | P90.xx | |

P91: Customized function group 2 | P91.xx | ||

P92: Customized function group 3 | P92.xx | ||

P93: Customized function group 4 | P93.xx | ||

State monitoring/fault record | State monitoring | P07: HMI group | P07.xx |

P17: State-check function group | P17.xx | ||

P18: Closed-loop vector state check function group | P18.xx | ||

P19: Extension card state check function group | P19.xx | ||

Fault record | / | P07.27: Type of present fault | |

P07.28: Type of the last fault | |||

P07.29: Type of the last but one fault | |||

P07.30: Type of the last but two fault | |||

P07.31: Type of the last but three fault | |||

P07.32: Type of the last but four fault | |||

Fault state | / | P07.33: Running frequency of present fault | |

P07.34: Ramps frequency of present fault | |||

P07.xx: xx state of the last but xx fault | |||

Clear fault history | / | Ensure to clear fault history? | |

Modified parameter | / | Pxx.xx has modified parameter 1 | |

Pxx.xx has modified parameter 2 | |||

Pxx.xx has modified parameter xx | |||

Motor parameter autotuning | / | / | Complete parameter rotary autotuning |

Complete parameter static autotuning | |||

Partial parameter static autotuning | |||

Parameter backup/restore default value | / | Operate the storage area 1: BACKUP01 | Upload local function parameter to keypad |

Download complete keypad function parameter | |||

Download key function parameters which are not in motor group | |||

Download keypad function parameters which are in motor group | |||

Operate the storage area 2: BACKUP012 | |||

Operate the storage area 3: BACKUP03 | |||

Restore function parameter to default value | Ensure to restore function parameters to default value? | ||

System setup | / | / | Language selection |

Time/date | |||

Backlight brightness regulation | |||

Backlight time adjustment | |||

Power-on guiding enable | |||

Power-on guiding settings | |||

Keyboard burning selection | |||

Fault time enable | |||

Control board burning selection |

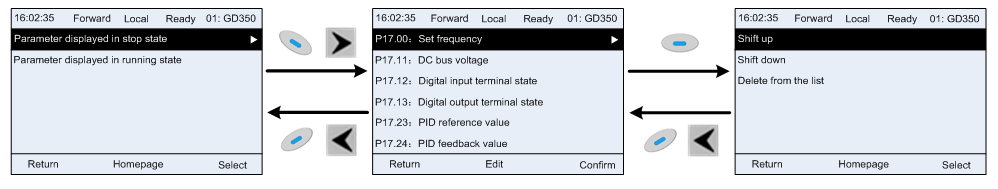

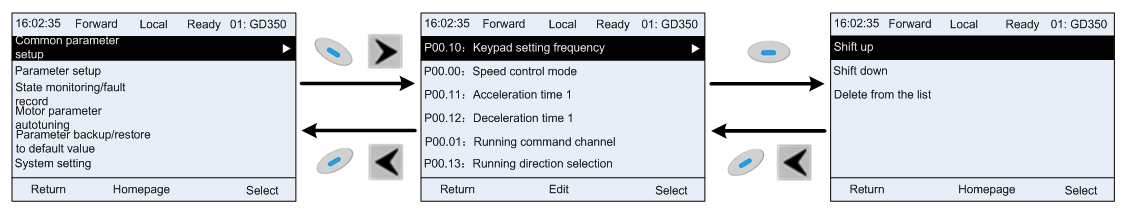

5.4.2 List edit

The monitoring items displayed in the parameter list of stop state can be added by users as needed (through the menu of the function code in state check group), and the list can also be edited by users eg "shift up", "shift down" and "delete from the list". The edit function is shown in the interface below.

Figure 5–10 List edit diagram 1

Press  key to enter edit interface, select the operation needed, and press

key to enter edit interface, select the operation needed, and press  key,

key,  key or

key or  key to confirm the edit operation and return to the previous menu (parameter list), the returned list is the list edited. If

key to confirm the edit operation and return to the previous menu (parameter list), the returned list is the list edited. If  key or

key or  key is pressed in edit interface wihouth selecting

key is pressed in edit interface wihouth selecting

edit operation, it will return to the previous menu (parameter list remain unchanged).

Note: For the parameter objects in the list header, shift-up operation will be invalid, and the same principle can be applied to the parameter objects in the list footer; after deleting a certain parameter, the parameter objects under it will be shifted up automatically.

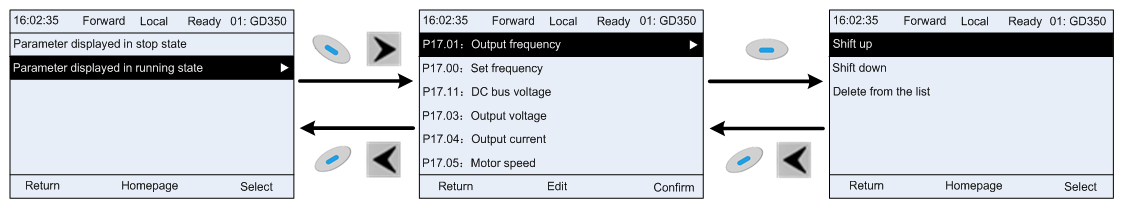

The monitoring items displayed in the parameter list of running state can be added by users as needed (through the menu of the function code in state check group), and the list can also be edited by users eg "shift up", "shift down" and "delete from the list". The edit function is shown in the interface below.

Figure 5–11 List edit diagram 2

The parameter list of common parameter setup can be added, deleted or adjusted by users as needed, including delete, shift-up and shift-down; the addition function can be set in a certain function code of a function group. The edit function is shown in the figure below.

Figure 5–12 List edit diagram 3

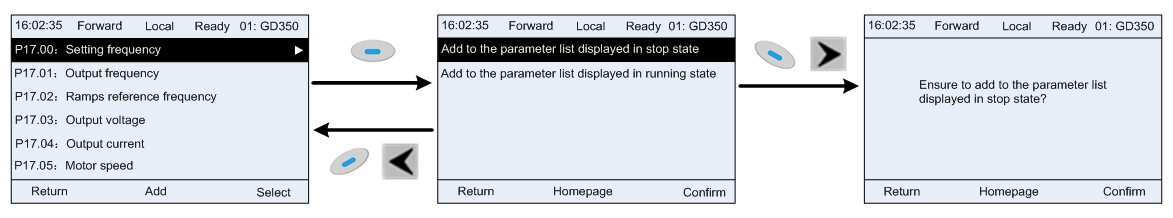

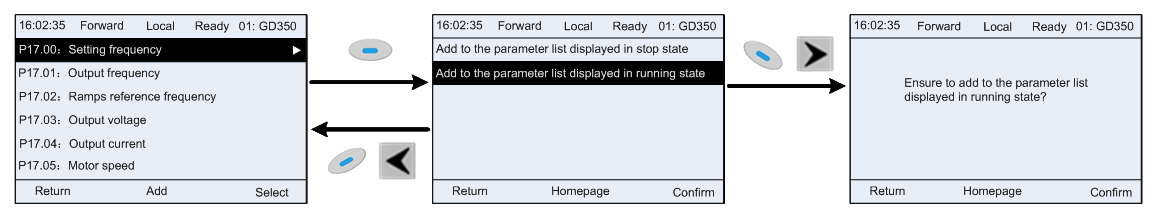

5.4.3 Add parameters to the parameter list displayed in stop/running state

In the fourth-level menu of "State monitoring", the parameters in the list can be added to the "parameter displayed in stop state" list or "parameter displayed in running state" list as shown below.

Figure 5–13 Add parameter diagram 1

Press  key to enter parameter addition interface, select the operation needed, and press

key to enter parameter addition interface, select the operation needed, and press  key,

key,  key or

key or  key to confirm the addition operation. If this parameter is not included in

key to confirm the addition operation. If this parameter is not included in

the "parameter displayed in stop state" list or "parameter displayed in running state" list, the parameter added will be at the end of the list; if the parameter is already in the "parameter displayed in stop state" list or "parameter displayed in running state" list, the addition operation will be invalid. If  key or

key or  key is pressed without selecting addition peration in "Addition" interface, it will return to monitoring parameter list menu.

key is pressed without selecting addition peration in "Addition" interface, it will return to monitoring parameter list menu.

Part of the monitoring parameters in P07 HMI group can be added to the "parameter displayed in stop state" list or "parameter displayed in running state" list; All the parameters in P17, P18 and P19 group can be added to the "parameter displayed in stop state" list or "parameter displayed in running state" list.

Up to 16 monitoring parameters can be added to the "parameter displayed in stop state" list; and up to 32 monitoring parameters can be added to the "parameter displayed in running state" list.

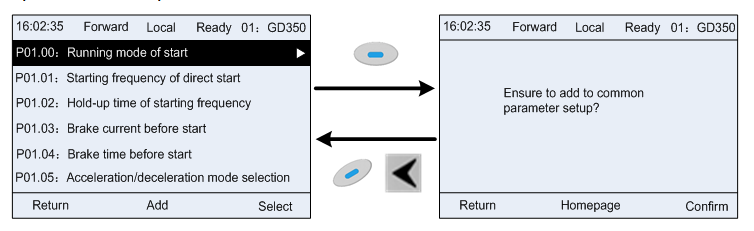

5.4.4 Add parameter to common parameter setup list

In fourth-level menu of "parameter setup" menu, the parameter in the list can be added to the "common parameter setup" list as shown below.

Figure 5–14 Add parameter diagram 2

Press  key to enter addition interface, and press

key to enter addition interface, and press  key,

key,  key or

key or  key to confirm the addition operation. If this parameter is not included in the original "common parameter setup" list, the newly-added parameter will be at the end of the list; if this parameter is already in the "common parameter setup" list, the addition operation will be invalid. If

key to confirm the addition operation. If this parameter is not included in the original "common parameter setup" list, the newly-added parameter will be at the end of the list; if this parameter is already in the "common parameter setup" list, the addition operation will be invalid. If  key or

key or  key is pressed without selecting addition operation, it will return to parameter setup list menu.

key is pressed without selecting addition operation, it will return to parameter setup list menu.

All the function code groups under parameter setup sub-menu can be added to "common parameter setup" list. Up to 64 function codes can be added to the "common parameter setup" list.

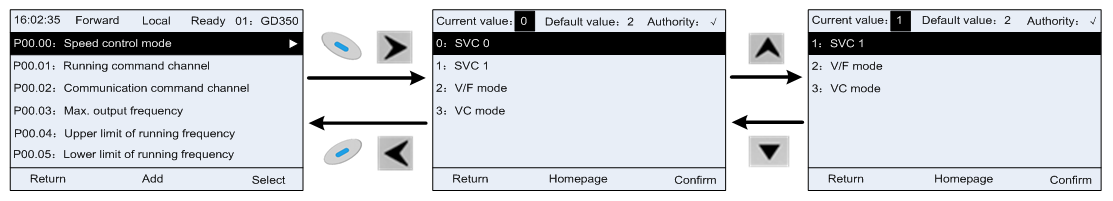

5.4.5 Parameter selection edit interface

In the fourth-level menu of "parameter setup" menu, press  key,

key,  key or

key or  key to enter

key to enter

parameter selection edit interface. After entering edit interface, current value will be highlighted. Press

key and

key and  key to edit current parameter value, and the corresponding parameter item of current value will be highlighted automatically. After parameter selection is done, press

key to edit current parameter value, and the corresponding parameter item of current value will be highlighted automatically. After parameter selection is done, press  key or

key or  key to save the selected parameter and return to the previous menu. In parameter selection edit interface, press

key to save the selected parameter and return to the previous menu. In parameter selection edit interface, press  key to maintain the parameter value and return to the previous menu.

key to maintain the parameter value and return to the previous menu.

Figure 5–15 Parameter selection edit interface

In parameter selection edit interface, the "authority" on the top right indicates whether this parameter is editable or not.

"√" indicates the set value of this parameter can be modified under current state.

"×" indicates the set value of this parameter cannot be modified under current state.

"Current value" indicates the value of current option.

"Default value" indicates the default value of this parameter.

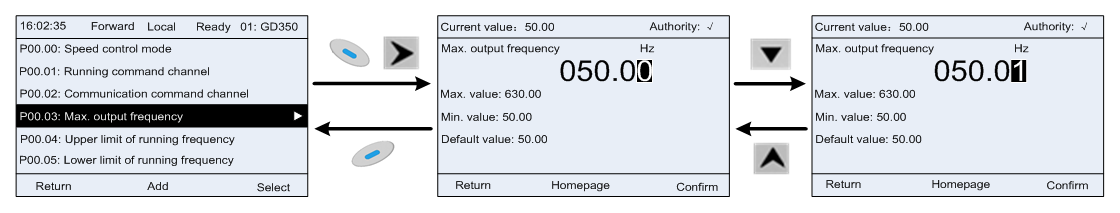

5.4.6 Parameter setup edit interface

In the fourth-level menu in "parameter setup" menu, press  key,

key,  key or

key or  key to enter

key to enter

parameter setup edit interface. After entering edit interface, set the parameter from low bit to high bit,

and the bit under setting will be highlighted. Press  key or

key or  key to increase or decrease the

key to increase or decrease the

parameter value (this operation is valid until the parameter value exceeds the max. value or min. value); press  or

or  to shift the edit bit. After parameters are set, press

to shift the edit bit. After parameters are set, press  key or

key or  key to save the set parameters and return to the previous parameter. In parameter setup edit interface, press

key to save the set parameters and return to the previous parameter. In parameter setup edit interface, press  to maintain the original parameter value and return to the previous menu.

to maintain the original parameter value and return to the previous menu.

Figure 5–16 Parameter setup edit interface

In parameter selection edit interface, the "authority" on the top right indicates whether this parameter can be modified or not.

"√" indicates the set value of this parameter can be modified under current state.

"×" indicates the set value of this parameter cannot be modified under current state.

"Current value" indicates the value saved last time.

"Default value" indicates the default value of this parameter.

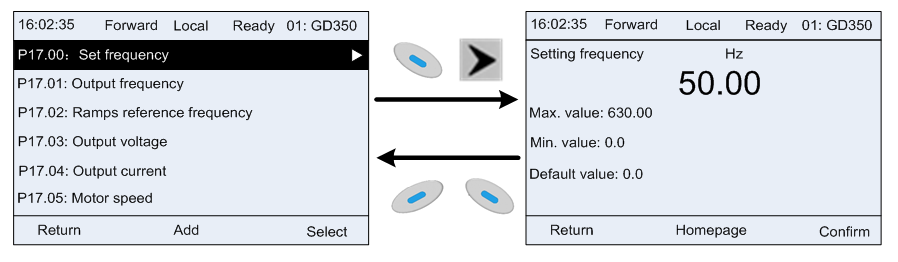

5.4.7 State monitoring interface

In the fourth-level menu of "state monitoring/fault record" menu, press  key,

key,  key or

key or

key to enter state monitoring interface. After entering state monitoring interface, the current parameter value will be displayed in real time, this value is the actually detected value which cannot be modified.

In state monitoring interface, press  key or

key or  key to return to the previous menu.

key to return to the previous menu.

Figure 5–17 State monitoring interface

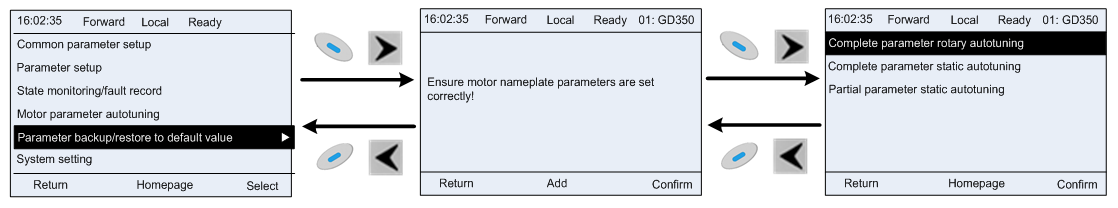

5.4.8 Motor parameter autotuning

In "Motor parameter autotuning" menu, press  key,

key,  key or

key or  key to enter motor

key to enter motor

parameter autotuning selection interface, however, before entering motor parameter autotuning interface, users must set the motor nameplate parameters correctly. After entering the interface, select motor autotuning type to carry out motor parameter autotuning. In motor parameter autotuning interface, press  key or

key or  key to return to the previous menu.

key to return to the previous menu.

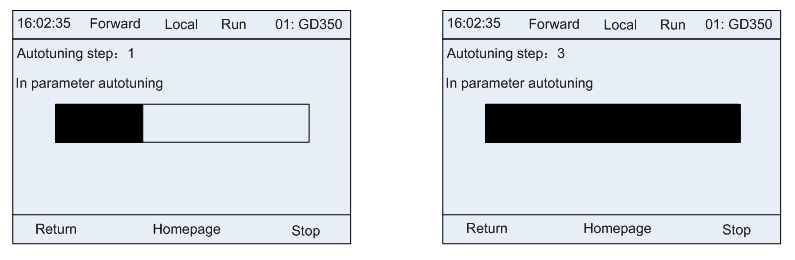

Figure 5–18 Parameter autotuning operation diagram

After selecting motor autotuning type, enter motor parameter autotuning interface, and press RUN key to start motor parameter autotuning. After autotuning is done, a prompt will pop out indicating autotuning is succeeded, and then it will return to the main interface of stop. During autotuning, users can press STOP/RST key to terminate autotuning; if any fault occur during autotuning, the keypad will pop out a fault interface.

Figure 5–19 Parameter autotuning finished

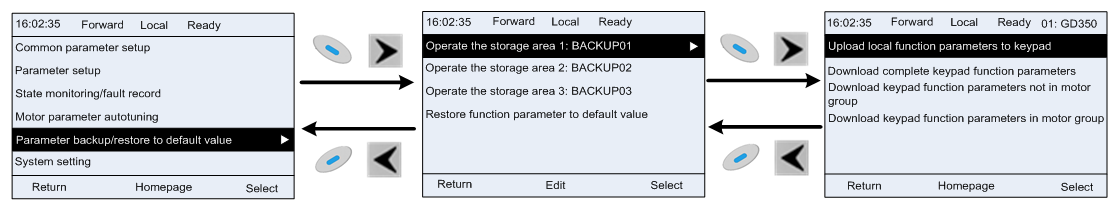

5.4.9 Parameter backup

In "parameter backup" menu, press  key,

key,  key or

key or  key to enter function parameter

key to enter function parameter

backup setting interface and function parameter restoration setup interface to upload/download VFD parameters, or restore VFD parameters to default value. The keypad has three different storage areas for parameter backup, and each storage area can save the parameters of one VFD, namely it can save parameters of three VFD in total.

Figure 5–20 Parameter backup operation diagram

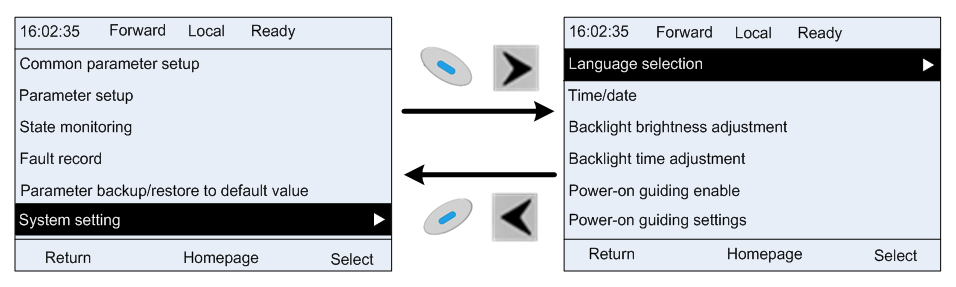

5.4.10 System setup

In "System setup" menu, press  key,

key,  key or

key or  key to enter system setup interface to

key to enter system setup interface to

set keypad language, time/date, backlight brightness, backlight time and restore parameters.

Note: Clock battery is not included, and the keypad time/date needs to be reset after power off. If time-keeping after power off is needed, users should purchase the clock batteries separately.

Figure 5–21 System setup diagram

5.4.11 Power-on guiding settings

The keyboard supports the power-on guiding function, mainly for the first power-on situation, guiding the user to enter the setting menu, and gradually implementing basic functions such as basic parameter setting, direction judgment, mode setting and autotuning. The power-on guiding enable menu guides the user to enable power-on to boot each time. Power-on guiding setup menu guides the user to set step by step according to the functions.

The power-on guide is shown as below.

First-level | Second-level | Third-level | Fourth-level | ||||

Language | 0: Simplified Chinese | Power-on guiding enable | 0: Powe-on each time | Whether to enter the power-on guiding settings? | 0:Yes | Whether to test the motor rotation direction? | Yes |

1: English | 1: Power on only once | 1:No | No | ||||

P00.06 A frequency command selection A frequency command selection | 0: Set via keypad | Press the JOG button first. It is currently forward, Is it consistent with the expectations? | Yes | ||||

1: Set via AI1 | No | ||||||

2: Set via AI2 | P02.00 Type of motor 1 | 0: Asynchronous motor | |||||

3: Set via AI3 | 1: Synchronous motor | ||||||

4: Set via high-speed pulse HDIA | P02.01 Rated power of asynchronous motor 1 | ||||||

5: Set via simple PLC program | P02.02 Rated frequency of asynchronous motor 1 | ||||||

6: Set via multi-step speed running | P02.03 Rated speed of asynchronous motor 1 | ||||||

7: Set via PID control | P02.04 Rated voltage of asynchronous motor 1 | ||||||

8: Set via Modbus communication | P02.05 Rated current of asynchronous motor 1 | ||||||

9: Set via PROFIBUS/CANopen/ | P02.15 Rated power of synchronous motor 1 | ||||||

10: Set via Ethernet communica- | P02.16 Rated frequency of synchronous motor 1 | ||||||

11: Set via high-speed pulse HDIB | P02.17 Number of pole pairs of synchronous motor 1 | ||||||

12: Set via pulse string AB | P02.18 Rated voltage of synchronous motor 1 | ||||||

13: Set via EtherCAT/ | P02.19 Rated current of synchronous motor 1 | ||||||

14: Set via PLC card | Whether to conduct autotuning? | Yes | |||||

15: Reserved | No | ||||||

P00.01 Running command channel | 0: Keypad | Motor parameter autotuning interface | |||||

1: Terminal | |||||||

2: Communication | |||||||

P00.02 Communi- Communi- | 0: Modbus | ||||||

1: PROFIBUS/ CANopen/ | |||||||

2: Ethernet | |||||||

3: EtherCAT/PROFINET | |||||||

4: PLC programmable card | |||||||

5: Bluetooth card | |||||||

P08.37 Enable/dis- | 0: Disable energy-consumption | ||||||

1: Enable energy-consumption | |||||||

P00.00 Speed control mode | 0: SVC 0 | ||||||

1: SVC 1 | |||||||

2: VF control | |||||||

3: VC | |||||||

P01.08 Stop mode | 0: Decelerate to stop | ||||||

1: Coast to stop | |||||||

P00.11 Acceleration time | |||||||

P00.12 Deceleration time | |||||||