5.5.1 What this section contains

This section introduces the function modules inside the VFD

|

|

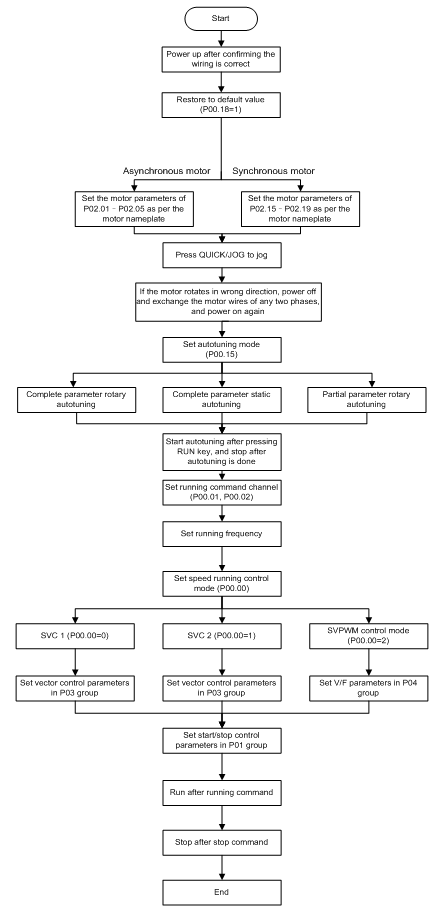

5.5.2 Common commissioning procedures

The common operation procedures are shown below (take motor 1 as an example).

Note: If fault occurred, rule out the fault cause according to "fault tracking".

The running command channel can be set by terminal commands besides P00.01 and P00.02.

Current running command channel P00.01 | Multi-function terminal function (36) Command switches to keypad | Multi-function terminal function (37) Command switches to terminal | Multi-function terminal function (38) Command switches to communication |

Keypad | / | Terminal | Communication |

Terminal | Keypad | / | Communication |

Communication | Keypad | Terminal | / |

Note: "/" means this multi-function terminal is valid under current reference channel.

Related parameter list:

Function code | Name | Detailed parameter description | Default value |

P00.00 | Speed control mode | 0: SVC 0 | 2 |

P00.01 | Running command channel | 0: Keypad 1: Terminal 2: Communication | 0 |

P00.02 | Communication running command channel | 0: Modbus | 0 |

P00.15 | Motor parameter autotuning | 0: No operation 1: Rotary autotuning 1; carry out comprehensive motor parameter autotuning; rotary autotuning is used in cases where high control precision is required; 2: Static autotuning 1 (comprehensive autotuning); static autotuning 1 is used in cases where the motor cannot be disconnected from load; 3: Static autotuning 2 (partial autotuning) ; when current motor is motor 1, only P02.06, P02.07 and P02.08 will be autotuned; when current motor is motor 2, only P12.06, P12.07 and P12.08 will be autotuned. 4: Rotary autotuning 2, which is similar to rotary autotuning 1 but is only applicable to asynchronous motors. 5: Rotary autotuning 3 (partial autotuning), which is only applicable to asynchronous motors. | 0 |

P00.18 | Function parameter restoration | 0: No operation 1: Restore to default value 2: Clear fault history Note: After the selected function operations are done, this function code will be restored to 0 automatically. Restoration to default value will clear the user password, this function should be used with caution. | 0 |

P02.00 | Type of motor 1 | 0: Asynchronous motor 1: Synchronous motor | 0 |

P02.01 | Rated power of asynchronous motor 1 | 0.1–3000.0kW | Depends on model |

P02.02 | Rated frequency of asynchronous motor 1 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P02.03 | Rated speed of asynchronous motor 1 | 1–60000rpm | Depends on model |

P02.04 | Rated voltage of asynchronous motor 1 | 0–1200V | Depends on model |

P02.05 | Rated current of asynchronous motor 1 | 0.8–6000.0A | Depends on model |

P02.15 | Rated power of synchronous motor 1 | 0.1–3000.0kW | Depends on model |

P02.16 | Rated frequency of synchronous motor 1 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P02.17 | Number of pole pairs of synchronous motor 1 | 1–50 | 2 |

P02.18 | Rated voltage of synchronous motor 1 | 0–1200V | Depends on model |

P02.19 | Rated current of synchronous motor 1 | 0.8–6000.0A | Depends on model |

P05.01–P05.06 | Function of multi-function digital input terminal (S1–S4, HDIA, HDIB) | 36: Command switches to keypad 37: Command switches to terminal 38: Command switches to communication | / |

P07.01 | Reserved variables | / | / |

P07.02 | QUICK/JOG key function | Range: 0x00–0x27 Ones: QUICK/JOG key function selection 0: No function 1: Jogging 2: Reserved 3: Switching between forward/reverse rotation 4: Clear UP/DOWN setting 5: Coast to stop 6: Switch running command reference mode by sequence 7: Reserved Tens: Reserved | 0x01 |

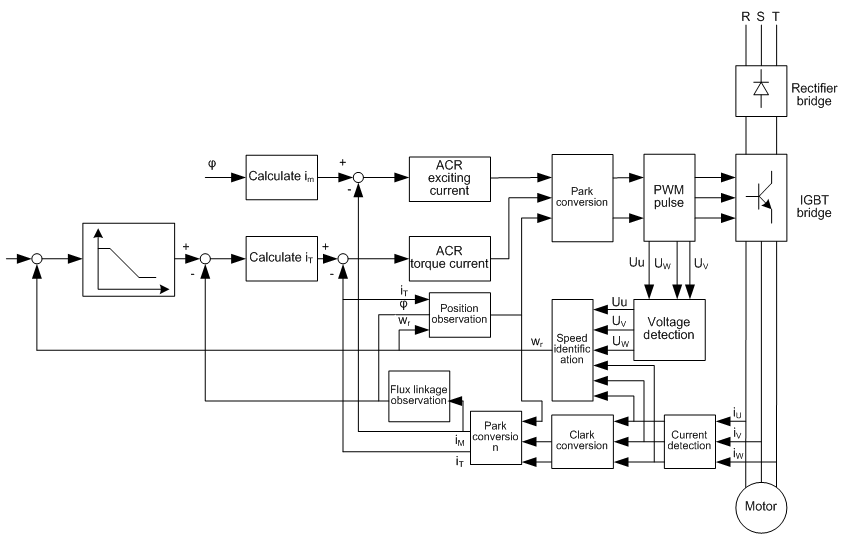

5.5.3 Vector control

Asynchronous motors are featured with high order, non-linear, strong coupling and multi-variables, which makes it very difficult to control asynchronous motors during actual application. The vector control theory aims to solve this problem through measuring and controlling the stator current vector of asynchronous motor, and decomposing the stator current vector into exciting current (current component which generates internal magnet field) and torque current (current component which generates torque) based on field orientation principle, and then controlling the amplitude value and phase position of these two components (namely, control the stator current vector of motor) to realize decoupling control of exciting current and torque current, thus achieving high-performance speed regulation of asynchronous motor.

The GD350 IP54 series VFD carries built-in speed sensor-less vector control algorithm, which can be used to drive the asynchronous motor and permanent-magnet synchronous motor simultaneously. As the core algorithm of vector control is based on accurate motor parameter model, the accuracy of motor parameters will impact the control performance of vector control. It is recommended to input accurate motor parameters and carry out motor parameter autotuning before vector operation.

As vector control algorithm is complicated, users should be cautious of regulation on dedicated function parameters of vector control.

Function code | Name | Description | Default value |

P00.00 | Speed control mode | 0: SVC 0 | 2 |

P00.15 | Motor parameter autotuning | 0: No operation 1: Rotary autotuning 1; carry out comprehensive motor parameter autotuning; rotary autotuning is used in cases where high control precision is required; 2: Static autotuning 1 (comprehensive autotuning); static autotuning 1 is used in cases where themotor cannot be disconnected from load; 3: Static autotuning 2 (partial autotuning) ; when current motor is motor 1, only P02.06, P02.07 and P02.08 will be autotuned; when current motor is motor 2, only P12.06, P12.07 and P12.08 will be autotuned. 4: Rotary autotuning 2, which is similar to rotary autotuning 1 but is only applicable to asynchronous motors. 5: Rotary autotuning 3 (partial autotuning), which is only applicable to asynchronous motors. | 0 |

P02.00 | Type of motor 1 | 0: Asynchronous motor 1: Synchronous motor | 0 |

P03.00 | Speed loop proportional gain 1 | 0–200.0 | 20.0 |

P03.01 | Speed loop integral time 1 | 0.000–10.000s | 0.200s |

P03.02 | Switching low point frequency | 0.00Hz–P03.05 | 5.00Hz |

P03.03 | Speed loop proportional gain 2 | 0–200.0 | 20.0 |

P03.04 | Speed loop integral time 2 | 0.000–10.000s | 0.200s |

P03.05 | Switching high point frequency | P03.02–P00.03 (max. output frequency) | 10.00Hz |

P03.06 | Speed loop output filter | 0–8 (corresponds to 0–28/10ms) | 0 |

P03.07 | Electromotion slip compensation coefficient of vector control | 50%–200% | 100% |

P03.08 | Brake slip compensation coefficient of vector control | 50%–200% | 100% |

P03.09 | Current loop proportional coefficient P | 0–65535 | 1000 |

P03.10 | Current loop integral coefficient I | 0–65535 | 1000 |

P03.32 | Torque control enable | 0:Disable | 0 |

P03.11 | Torque setup mode selection | 1: Keypad (P03.12) 2: AI1 3: AI2 4: AI3 5: Pulse frequency HDIA 6: Multi-step torque 7: Modbus communication 8: PROFIBUS/CANopen/DeviceNet communication 9: Ethernet communication 10: Pulse frequency HDIB 11: EtherCAT/PROFINET communication 12: PLC Note: For setting sources 2–6 and 10, 100% corresponds to three times the rated motor current. | 1 |

P03.12 | Torque set by keypad | -300.0%–300.0% (rated motor current) | 50.0% |

P03.13 | Torque reference filter time | 0.000–10.000s | 0.010s |

P03.14 | Source of upper limit frequency setup of forward rotation in torque control | 0: Keypad (P03.16) 1: AI1 (100% corresponds to max. frequency) 2: AI2 (the same as above) 3: AI3 (the same as above) 4: Pulse frequency HDIA (the same as above) 5: Multi-step (the same as above) 6: Modbus communication (the same as above) 7: PROFIBUS/CANopen/DeviceNet communication(the same as above) 8: Ethernet communication (the same as above) 9: Pulse frequency HDIB (the same as above) 10: EtherCAT/PROFINET communication 11: PLC 12: Reserved Note: Source 5.51, 100% relative to the max. frequency. | 0 |

P03.15 | Source of upper limit frequency setup of reverse rotation in torque control | 0: Keypad (P03.17) 5.51: the same as P03.14 | 0 |

P03.16 | Keypad limit value of upper limit frequency of forward rotation in torque control | Value range: 0.00 Hz–P00.03 (max. output frequency) | 50.00Hz |

P03.17 | Keypad limit value of upper limit frequency of reverse rotation in torque control | 50.00Hz | |

P03.18 | Source of upper limit setup of the torque when motoring | 0: Keypad (P03.20) 1: AI1 2: AI2 3: AI3 4: Pulse frequency HDIA 5: Modbus communication 6: PROFIBUS/CANopen/DeviceNet communication 7: Ethernet communication 8: Pulse frequency HDIB 9: EtherCAT/PROFINET communication 10: PLC 11: Reserved Note: For setting sources 1–4 and 8, 100% corresponds to three times the rated motor current. | 0 |

P03.19 | Source of upper limit setup of brake torque | 0: Keypad (P03.21) 5.50: the same as P03.18 | 0 |

P03.20 | Set upper limit of the torque when motoring via keypad | 0.0–300.0% (rated motor current) | 180.0% |

P03.21 | Set upper limit of brake torque via keypad | 180.0% | |

P03.22 | Flux-weakening coefficient in constant power area | 0.1–2.0 | 0.3 |

P03.23 | Min. flux-weakening point in constant power area | 10%–100% | 20% |

P03.24 | Max. voltage limit | 0.0–120.0% | 100.0% |

P03.25 | Pre-exciting time | 0.000–10.000s | 0.300s |

P03.32 | Torque control enable | 0:Disable | 0 |

P03.33 | Flux weakening integral gain | 0–8000 | 1200 |

P03.35 | Control optimization setting | 0–0x5.51 Ones place: Torque command selection 0: Torque reference 1: Torque current reference Tens place: Reserved 0: Reserved 1: Reserved Hundreds place: Whether to enable ASR integral separation 0: Disable 1: Enable Thousands place: Reserved 0: Reserved 1: Reserved | 0x0000 |

P03.36 | ASR differential gain | 0.00–10.00s | 0.00s |

P03.37 | High-frequency ACR proportional coefficient | In the closed-loop vector control mode (P00.00=3), when the frequency is lower than the ACR high-frequency switching threshold (P03.39), the ACR PI parameters are P03.09 and P03.10; and when the frequency is higher than the ACR high-frequency switching threshold (P03.39), the ACR PI parameters are P03.37 and P03.38. Setting range of P03.37: 0–65535 Setting range of P03.38: 0–65535 Setting range of P03.39: 0.0–100.0% (in relative to the maximum frequency) | 1000 |

P03.38 | High-frequency ACR integral coefficient | 1000 | |

P03.39 | ACR high-frequency switching threshold | 100.0% | |

P17.32 | Flux linkage | 0.0–200.0% | 0.0% |

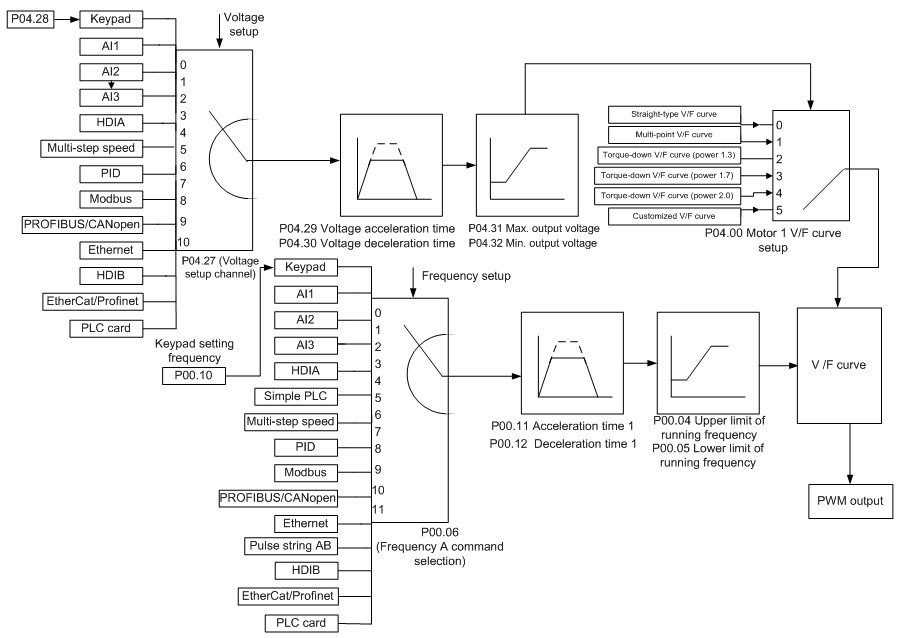

5.5.4 SVPWM control mode

The GD350 IP54 series VFD also carries built-in SVPWM control function. SVPWM mode can be used in cases where mediocre control precision is enough. In cases where a VFD needs to drive multiple motors, it is also recommended to adopt SVPWM control mode.

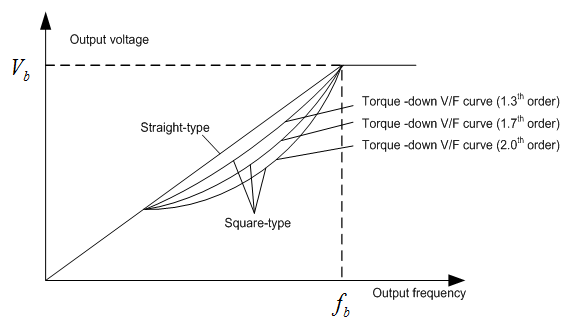

The GD350 IP54 series VFD provides multiple kinds of V/F curve modes to meet different field needs. Users can select corresponding V/F curve or set the V/F curve as needed.

Suggestions:

1. For the load featuring constant moment, eg, conveyor belt which runs in straight line, as the moment should be constant during the whole running process, it is recommended to adopt straight-type V/F curve.

2. For the load featuring decreasing moment, eg, fan and water pump, as the relation between its actual torque and speed is squared or cubed, it is recommended to adopt the V/F curve corresponds to power 1.3, 1.7 or 2.0.

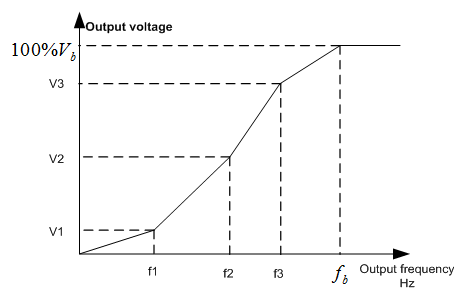

The GD350 IP54 series VFD also provides multi-point V/F curve. Users can alter the V/F curve outputted by VFD through setting the voltage and frequency of the three points in the middle. The whole curve consists of five points starting from (0Hz, 0V) and ending in (fundamental motor frequency, rated motor voltage). During setup, it is required that 0≤f1≤f2≤f3≤fundamental motor frequency, and 0≤V1≤V2≤V3≤rated motor voltage

The GD350 IP54 series VFD provides dedicated function codes for SVPWM control mode. Users can improve the performance of SVPWM through settings.

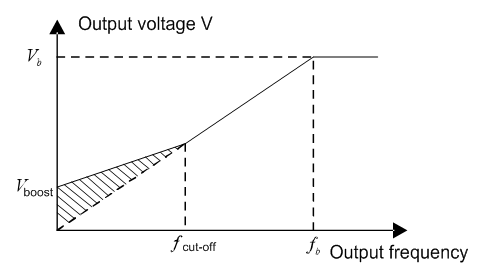

1. Torque boost

Torque boost function can effectively compensate for the low-speed torque performance during SVPWM control. Automatic torque boost has been set by default to enable the VFD to adjust the torque boost value based on actual load conditions.

Note:

(1) Torque boost is effective only under torque boost cut-off frequency;

(2) If the torque boost is too large, low-frequency vibration or overcurrent may occur to the motor, if such situation occurs, lower the torque boost value.

2. Energy-saving run

During actual running, the VFD can search for the max. efficiency point to keep running in the most efficient state to save energy.

Note:

(1) This function is generally used in light load or no-load cases.

(2) This function does for fit in cases where load transient is required.

3. V/F slip compensation gain

SVPWM control belongs to open-loop mode, which will cause motor speed to fluctuate when motor load transients. In cases where strict speed requirement is needed, users can set the slip compensation gain to compensate for the speed variation caused by load fluctuation through internal output adjustment of VFD.

The set range of slip compensation gain is 0–200%, in which 100% corresponds to rated slip frequency.

Note: Rated slip frequency= (rated synchronous speed of motor-rated speed of motor) × number of motor pole pairs/60

4. Oscillation control

Motor oscillation often occurs in SVPWM control in large-power drive applications. To solve this problem, the GD350 IP54 series VFD sets two function codes to control the oscillation factor, and users can set the corresponding function code based on the occurrence frequency of oscillation.

Note: The larger the set value, the better the control effect, however, if the set value is too large, it may easily lead to too large VFD output current.

Customized V/F curve (V/F separation) function:

When selecting customized V/F curve function, users can set the reference channels and acceleration/deceleration time of voltage and frequency respectively, which will form a real-time V/F curve through combination.

Note: This kind of V/F curve separation can be applied in various frequency-conversion power sources, however, users should be cautious of parameter setup as improper setup may damage the machine.

Function code | Name | Detailed parameter description | Default value |

P00.00 | Speed control mode | 0: SVC 0 | 2 |

P00.03 | Max. output frequency | P00.04–400.00Hz | 50.00Hz |

P00.04 | Upper limit of running frequency | P00.05–P00.03 | 50.00Hz |

P00.05 | Lower limit of running frequency | 0.00Hz–P00.04 | 0.00Hz |

P00.11 | Acceleration time 1 | 0.0–3600.0s | Depends on model |

P00.12 | Deceleration time 1 | 0.0–3600.0s | Depends on model |

P02.00 | Type of motor 1 | 0: Asynchronous motor 1: Synchronous motor | 0 |

P02.02 | Rated power of asynchronous motor 1 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P02.04 | Rated voltage of asynchronous motor 1 | 0–1200V | Depends on model |

P04.00 | V/F curve setting of motor 1 | 0: Straight-type V/F curve 1: Multi-point V/F curve 2: Torque-down V/F curve (power 1.3) 3: Torque-down V/F curve (power 1.7) 4: Torque-down V/F curve (power 2.0) 5: Customized V/F (V/F separation) | 0 |

P04.01 | Torque boost of motor 1 | 0.0%: (automatic) 0.1%–10.0% | 0.0% |

P04.02 | Motor 1 torque boost cut-off | 0.0%–50.0% (rated frequency of motor 1) | 20.0% |

P04.03 | V/F frequency point 1 of motor 1 | 0.00Hz–P04.05 | 0.00Hz |

P04.04 | V/F voltage point 1 of motor 1 | 0.0%–110.0% | 0.0% |

P04.05 | V/F frequency point 2 of motor 1 | P04.03– P04.07 | 0.00Hz |

P04.06 | V/F voltage point 2 of motor 1 | 0.0%–110.0% | 0.0% |

P04.07 | V/F frequency point 3 of motor 1 | P04.05– P02.02 or P04.05– P02.16 | 0.00Hz |

P04.08 | V/F voltage point 3 of motor 1 | 0.0%–110.0% | 0.0% |

P04.09 | V/F slip compensation gain of motor 1 | 0.0–200.0% | 100.0% |

P04.10 | Low-frequency oscillation control factor of motor 1 | 0–100 | 10 |

P04.11 | High-frequency oscillation control factor of motor 1 | 0–100 | 10 |

P04.12 | Oscillation control threshold of motor 1 | 0.00Hz–P00.03 (max. output frequency) | 30.00Hz |

P04.13 | V/F curve setup of motor 2 | 0: Straight V/F curve; 1: Multi-point V/F curve 2: Torque-down V/F curve (1.3th order) 3: Torque-down V/F curve (1.7th order) 4: Torque-down V/F curve (2.0th order) 5: Customize V/F (V/F separation) | 0 |

P04.14 | Torque boost of motor 2 | 0.0%: (automatic) 0.1%–10.0% | 0.0% |

P04.15 | Motor 2 torque boost cut-off | 0.0%–50.0% (rated frequency of motor 1) | 20.0% |

P04.16 | V/F frequency point 1 of motor 2 | 0.00Hz–P04.18 | 0.00Hz |

P04.17 | V/F voltage point 1 of motor 2 | 0.0%–110.0% | 0.0% |

P04.18 | V/F frequency point 2 of motor 2 | P04.16– P04.20 | 0.00Hz |

P04.19 | V/F voltage point 2 of motor 2 | 0.0%–110.0% | 0.0% |

P04.20 | V/F frequency point 3 of motor 2 | P04.18– P02.02 or P04.18– P02.16 | 0.00Hz |

P04.21 | V/F voltage point 3 of motor 2 | 0.0%–110.0% | 0.0% |

P04.22 | V/F slip compensation gain of motor 2 | 0.0–200.0% | 100.0% |

P04.23 | Low-frequency oscillation control factor of motor 2 | 0–100 | 10 |

P04.24 | High-frequency oscillation control factor of motor 2 | 0–100 | 10 |

P04.25 | Oscillation control threshold of motor 2 | 0.00Hz–P00.03 (max. output frequency) | 30.00Hz |

P04.26 | Energy-saving run | 0: No 1: Automatic energy-saving run | 0 |

P04.27 | Channel of voltage setup | 0: Keypad; output voltage is determined by P04.28 1: AI1 2: AI2 3: AI3 4: HDIA 5: Multi-step 6: PID 7: Modbus communication 8: PROFIBUS/CANopen communication 9: Ethernet communication 10: HDIB 11: EtherCAT/PROFINET communication 12: PLC card 13: Reserved | 0 |

P04.28 | Set voltage value via keypad | 0.0%–100.0% (rated motor voltage) | 100.0% |

P04.29 | Voltage acceleration time | 0.0–3600.0s | 5.0s |

P04.30 | Voltage deceleration time | 0.0–3600.0s | 5.0s |

P04.31 | Max. output voltage | P04.32–100.0% (rated motor voltage) | 100.0% |

P04.32 | Min. output voltage | 0.0%–P04.31 (rated motor voltage) | 0.0% |

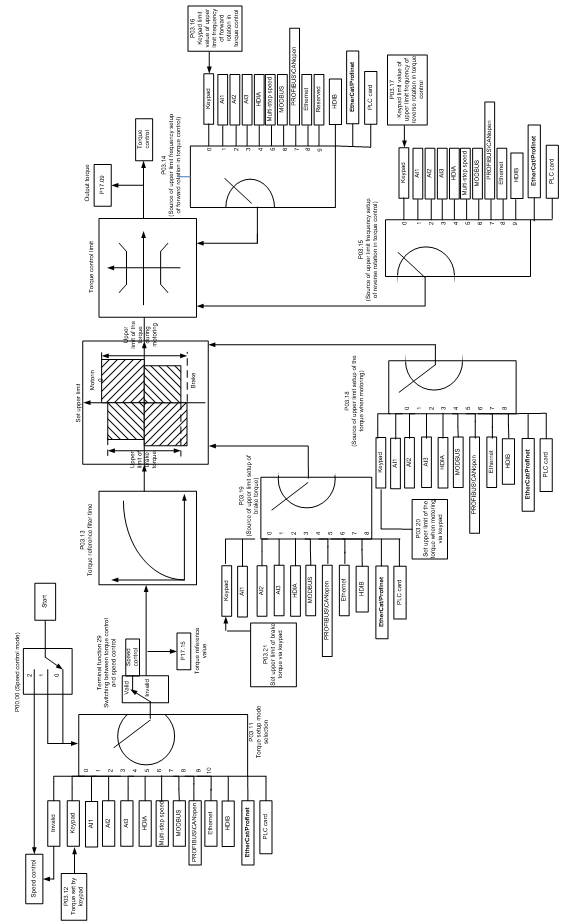

5.5.5 Torque control

The GD350 IP54 series VFD supports torque control and speed control. Speed control mode aims to stabilize the speed to keep the set speed consistent with the actual running speed, meanwhile, the max. load-carrying capacity is restricted by torque limit. Torque control mode aims to stabilize the torque to keep the set torque consistent with the actual output torque, meanwhile, the output frequency is restricted by upper/lower limit.

Function code | Name | Detailed parameter description | Default value |

P00.00 | Speed control mode | 0: SVC 0 | 2 |

P03.32 | Torque control enable | 0: Disable | 0 |

P03.11 | Torque setup mode selection | 1: Keypad (P03.12) 2: AI1 3: AI2 4: AI3 5: Pulse frequency HDIA 6: Multi-step torque 7: Modbus communication 8: PROFIBUS/CANopen/DeviceNet communication 9: Ethernet communication 10: Pulse frequency HDIB 11: EtherCAT/PROFINET communication 12: PLC Note: For setting sources 2–6 and 10, 100% corresponds to three times the rated motor current. | 1 |

P03.12 | Torque set by keypad | -300.0%–300.0% (rated motor current) | 50.0% |

P03.13 | Torque reference filter time | 0.000–10.000s | 0.010s |

P03.14 | Source of upper limit frequency setup of forward rotation in torque control | 0: Keypad (P03.16) 1: AI1 (100% corresponds to max. frequency) 2: AI2 (the same as above) 3: AI3 (the same as above) 4: Pulse frequency HDIA (the same as above) 5: Multi-step (the same as above) 6: Modbus communication (the same as above) 7: PROFIBUS/CANopen/DeviceNet communication (the same as above) 8: Ethernet communication (the same as above) 9: Pulse frequency HDIB (the same as above) 10: EtherCAT/PROFINET communication 11: PLC 12: Reserved Note: Source 5.51, 100% relative to the max. frequency | 0 |

P03.15 | Source of upper limit frequency setup of reverse rotation in torque control | 0: Keypad (P03.17) 1: AI1 (100% corresponds to max. frequency) 2: AI2 (the same as above) 3: AI3 (the same as above) 4: Pulse frequency HDIA (the same as above) 5: Multi-step (the same as above) 6: Modbus communication (the same as above) 7: PROFIBUS/CANopen/DeviceNet communication (the same as above) 8: Ethernet communication (the same as above) 9: Pulse frequency HDIB (the same as above) 10: EtherCAT/PROFINET communication 11: PLC 12: Reserved Note: Source 5.51, 100% relative to the max. frequency | 0 |

P03.16 | Keypad limit value of upper limit frequency of forward rotation in torque control | 0.00Hz–P00.03 (max. output frequency) | 50.00 Hz |

P03.17 | Keypad limit value of upper limit frequency of reverse rotation in torque control | 0.00Hz–P00.03 (max. output frequency) | 50.00 Hz |

P03.18 | Source of upper limit setup of the torque during motoring | 0: Keypad (P03.20) 1: AI1 2: AI2 3: AI3 4: Pulse frequency HDIA 5: Modbus communication 6: PROFIBUS/CANopen/DeviceNet communication 7: Ethernet communication 8: Pulse frequency HDIB 9: EtherCAT/PROFINET communication 10: PLC 11: Reserved Note: For setting sources 1–4 and 8, 100% corresponds to three times the rated motor current. | 0 |

P03.19 | Source of upper limit setup of brake torque | 0: Keypad (P03.21) 5.50: the same as P03.18 | 0 |

P03.20 | Set upper limit of the torque when motoring via keypad | 0.0–300.0% (rated motor current) | 180.0% |

P03.21 | Set upper limit of brake torque via keypad | 0.0–300.0% (rated motor current) | 180.0% |

P17.09 | Motor output torque | -250.0–250.0% | 0.0% |

P17.15 | Torque reference value | -300.0–300.0% (rated motor current) | 0.0% |

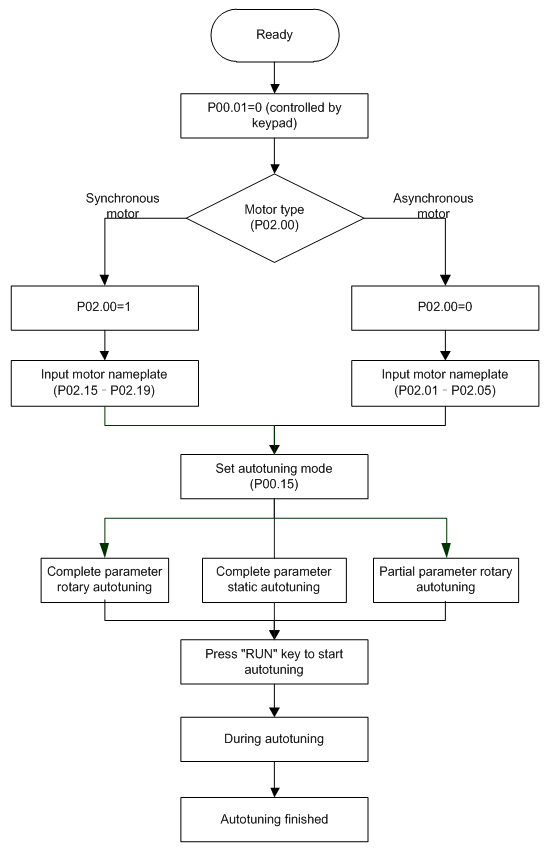

5.5.6 Motor parameter

|

|

| If the motor has been connected to load, do not carry out rotary autotuning; otherwise, misact or damage may occur to the VFD. If rotary autotuning is carried out on a motor which has been connected to load, wrong motor parameters and motor misacts may occur. Disconnect the load to carry out autotuning if necessary. |

The GD350 IP54 series VFD can drive asynchronous motors and synchronous motors, and it supports two sets of motor parameters, which can be switched over by multi-function digital input terminals or communication modes.

The control performance of the VFD is based on accurate motor model; therefore, users need to carry out motor parameter autotuning before running the motor for the first time (take motor 1 as an example).

Note:

1. Motor parameters must be set correctly according to motor nameplate;

2. If rotary autotuning is selected during motor autotuning, it is a must to disconnect the motor from load to put the motor in static and no-load state, failed to do so may lead to inaccurate autotuned results. At this time, the asynchronous motor can autotune P02.06–P02.10, and synchronous motor can autotune P02.20–P02.23

3. If static autotuning is selected during motor autotuning, there is no need to disconnect the motor from load, as only part of the motor parameters have been autotuned, the control performance may be impacted, under such situation, the asynchronous motor can autotune P02.06–P02.10, while synchronous motor can autotune P02.20–P02.22, P02.23 (counter-emf constant of synchronous motor 1) can be obtained via calculation.

4. Motor autotuning can be carried out on current motor only, if users need to perform autotuning on the other motor, switch over the motor through selecting the switch-over channel of motor 1 and motor 2 by setting the ones of P08.31.

Related parameter list:

Function code | Name | Detailed parameter description | Default value |

P00.01 | Running command channel | 0: Keypad 1: Terminal 2: Communication | 0 |

P00.15 | Motor parameter autotuning | 0: No operation 1: Rotary autotuning 1; carry out comprehensive motor parameter autotuning; rotary autotuning isused in cases where high control precision is required; 2: Static autotuning 1 (comprehensive autotuning); static autotuning 1 is used in cases where the motor cannot be disconnected from load; 3: Static autotuning 2 (partial autotuning) ; when current motor is motor 1, only P02.06, P02.07 and P02.08 will be autotuned; when current motor is motor 2, only P12.06, P12.07 and P12.08 will be autotuned. 4: Rotary autotuning 2, which is similar to rotary autotuning 1 but is only applicable to asynchronous motors. 5: Rotary autotuning 3 (partial autotuning), which is only applicable to asynchronous motors. | 0 |

P02.00 | Type of motor 1 | 0: Asynchronous motor 1: Synchronous motor | 0 |

P02.01 | Rated power of asynchronous motor 1 | 0.1–3000.0kW | Depends on model |

P02.02 | Rated frequency of asynchronous motor 1 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P02.03 | Rated speed of asynchronous motor 1 | 1–60000rpm | Depends on model |

P02.04 | Rated voltage of asynchronous motor 1 | 0–1200V | Depends on model |

P02.05 | Rated current of asynchronous motor 1 | 0.8–6000.0A | Depends on model |

P02.06 | Stator resistance of asynchronous motor 1 | 0.001–65.535Ω | Depends on model |

P02.07 | Rotor resistance of asynchronous motor 1 | 0.001–65.535Ω | Depends on model |

P02.08 | Leakage inductance of asynchronous motor 1 | 0.1–6553.5mH | Depends on model |

P02.09 | Mutual inductance of asynchronous motor 1 | 0.1–6553.5mH | Depends on model |

P02.10 | No-load current of asynchronous motor 1 | 0.1–6553.5A | Depends on model |

P02.15 | Rated power of synchronous motor 1 | 0.1–3000.0kW | Depends on model |

P02.16 | Rated frequency of synchronous motor 1 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P02.17 | Number of pole pairs of synchronous motor 1 | 1–50 | 2 |

P02.18 | Rated voltage of synchronous motor 1 | 0–1200V | Depends on model |

P02.19 | Rated current of synchronous motor 1 | 0.8–6000.0A | Depends on model |

P02.20 | Stator resistance of synchronous motor 1 | 0.001–65.535Ω | Depends on model |

P02.21 | Direct-axis inductance of synchronous motor 1 | 0.01–655.35mH | Depends on model |

P02.22 | Quadrature-axis inductance of synchronous motor 1 | 0.01–655.35mH | Depends on model |

P02.23 | Counter-emf constant of synchronous motor 1 | 0–10000 | 300 |

P05.01–P05.06 | Function of multi-function digital input terminal (S1–S4, HDIA, HDIB) | 35: Motor 1 switches to motor 2 | / |

P08.31 | Switching between motor 1 and motor 2 | 0x00–0x14 Ones: Switch-over channel 0: Switch over by terminal 1: Switch over by Modbus communication 2: Switch over by PROFIBUS/CANopen/DeviceNet 3: Switch over by Ethernet communication 4: Switch over by EtherCAT/PROFINET communication Tens: Motor switch-over during running 0: Disable switch-over during running 1: Enable switch-over during running | 00 |

P12.00 | Type of motor 2 | 0: Asynchronous motor 1: Synchronous motor | 0 |

P12.01 | Rated power of asynchronous motor 2 | 0.1–3000.0kW | Depends on model |

P12.02 | Rated frequency of asynchronous motor 2 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P12.03 | Rated speed of asynchronous motor 2 | 1–36000rpm | Depends on model |

P12.04 | Rated voltage of asynchronous motor 2 | 0–1200V | |

P12.05 | Rated current of asynchronous motor 2 | 0.8–6000.0A | |

P12.06 | Stator resistance of asynchronous motor 2 | 0.001–65.535Ω | |

P12.07 | Rotor resistance of asynchronous motor 2 | 0.001–65.535Ω | |

P12.08 | Leakage inductance of asynchronous motor 2 | 0.1–6553.5mH | |

P12.09 | Mutual inductance of asynchronous motor 2 | 0.1–6553.5mH | |

P12.10 | No-load current of asynchronous motor 2 | 0.1–6553.5A | |

P12.15 | Rated power of synchronous motor 2 | 0.1–3000.0kW | |

P12.16 | Rated frequency of synchronous motor 2 | 0.01Hz–P00.03 (max. output frequency) | 50.00Hz |

P12.17 | Number of pole pairs of synchronous motor 2 | 1–50 | 2 |

P12.18 | Rated voltage of synchronous motor 2 | 0–1200V | Depends on model |

P12.19 | Rated current of synchronous motor 2 | 0.8–6000.0A | Depends on model |

P12.20 | Stator resistance of synchronous motor 2 | 0.001–65.535Ω | Depends on model |

P12.21 | Direct-axis inductance of synchronous motor 2 | 0.01–655.35mH | Depends on model |

P12.22 | Quadrature-axis inductance of synchronous motor 2 | 0.01–655.35mH | Depends on model |

P12.23 | Counter-emf constant of synchronous motor 2 | 0–10000 | 300 |

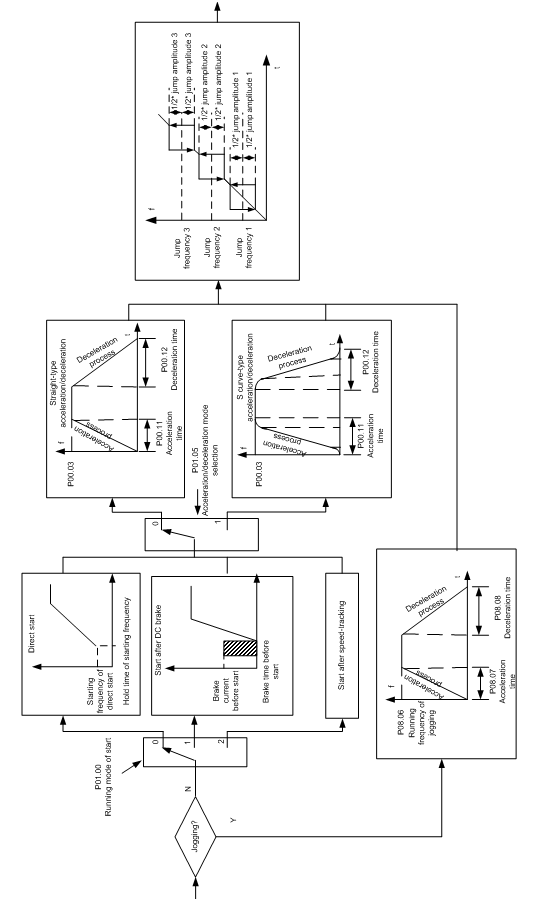

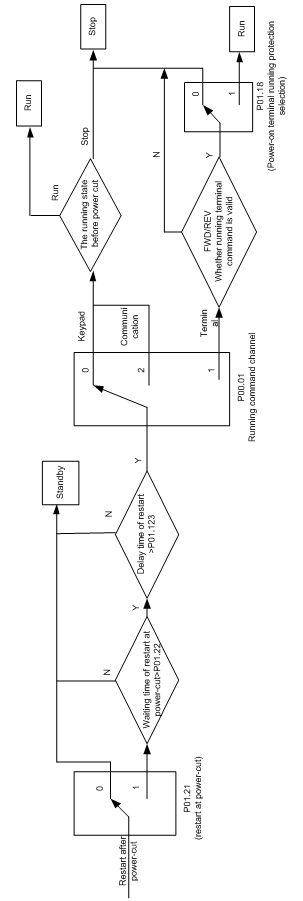

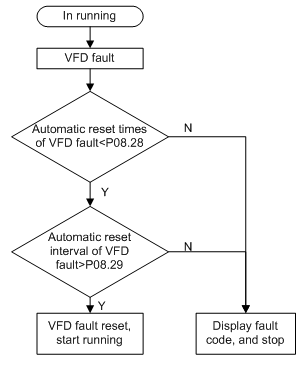

5.5.7 Start/stop control

The start/stop control of the VFD is divided into three states: start after running command at power-up; start after restart-at-power-cut function is effective; start after automatic fault reset. Descriptions for these three start/stop control states are presented below.

There are three start modes for the VFD, which are start at starting frequency, start after DC brake, and start after speed-tracking. Users can select the proper start mode based on field conditions.

For large-inertia load, especially in cases where reversal may occur, users can choose to start after DC brake or start after speed-racking.

Note: It is recommended to drive synchronous motors in direct start mode.

1. Logic diagram for running command after power-up

2. Logic diagram for restart after power-cut

3. Logic diagram for restart after automatic fault reset

Related parameter list:

Function code | Name | Detailed parameter description | Default value |

P00.01 | Running command channel | 0: Keypad 1: Terminal 2: Communication | 0 |

P00.11 | Acceleration time 1 | 0.0–3600.0s | Depends on model |

P00.12 | Deceleration time 1 | 0.0–3600.0s | Depends on model |

P01.00 | Running mode of start | 0: Direct start 1: Start after DC brake 2: Start after speed-track 1 3: Start after speed-track 2 | 0 |

P01.01 | Starting frequency of direct start | 0.00–50.00Hz | 0.50Hz |

P01.02 | Hold time of starting frequency | 0.0–50.0s | 0.0s |

P01.03 | DC brake current before start | 0.0–100.0% | 0.0% |

P01.04 | DC brake time before start | 0.00–50.00s | 0.00s |

P01.05 | Acceleration/deceleration mode | 0: Straight line 1: S curve Note: If mode 1 is selected, it is required to set P01.07, P01.27 and P01.08 accordingly | 0 |

P01.08 | Stop mode | 0: Decelerate to stop 1: Coast to stop | 0 |

P01.09 | Starting frequency of DC brake after stop | 0.00Hz–P00.03 (max. output frequency) | 0.00Hz |

P05.50 | Waiting time of DC brake after stop | 0.00–50.00s | 0.00s |

P05.51 | DC brake current of stop | 0.0–100.0% | 0.0% |

P05.52 | DC brake time of stop | 0.00–50.00s | 0.00s |

P05.53 | Deadzone time of forward/reverse rotation | 0.0–3600.0s | 0.0s |

P05.54 | Forward/reverse rotation switch-over mode | 0: switch over after zero frequency 1: switch over after starting frequency 2: switch over after passing stop speed and delay | 0 |

P05.55 | Stop speed | 0.00–100.00Hz | 0.50 Hz |

P05.56 | Stop speed detection mode | 0: Set value of speed (the only detection mode valid in SVPWM mode) 1: Detection value of speed | 1 |

P05.58 | Power-on terminal running protection selection | 0: Terminal running command is invalid at power up 1: Terminal running command is valid at power up | 0 |

P05.59 | Action selection when the running frequency is below lower limit (lower limit should be larger than 0) | 0: Run at the lower limit frequency 1: Stop 2: Sleep | 0 |

P01.20 | Wake-up-from-sleep delay | 0.0–3600.0s (valid when P05.59 is 2) | 0.0s |

P01.21 | Restart after power cut | 0: Restart is disabled 1: Restart is enabled | 0 |

P01.22 | Waiting time of restart after power cut | 0.0–3600.0s (valid when P01.21 is 1) | 1.0s |

P01.23 | Start delay | 0.0–60.0s | 0.0s |

P01.24 | Stop speed delay | 0.0–100.0s | 0.0s |

P01.25 | Open-loop 0Hz output selection | 0: No voltage output 1: With voltage output 2: Output as per DC brake current of stop | 0 |

P01.26 | Deceleration time of emergency-stop | 0.0–60.0s | 2.0s |

P01.27 | Time of starting section of deceleration S curve | 0.0–50.0s | 0.1s |

P01.28 | Time of ending section of deceleration S curve | 0.0–50.0s | 0.1s |

P01.29 | Short-circuit brake current | 0.0–150.0% (rated VFD current) | 0.0% |

P01.30 | Hold time of short-circuit brake at startup | 0.00–50.00s | 0.00s |

P01.31 | Hold time of short-circuit brake at stop | 0.00–50.00s | 0.00s |

P01.32 | Pre-exciting time of jogging | 0–10.000s | 0.000s |

P01.33 | Starting frequency of braking for jogging to stop | 0–P00.03 | 0.00Hz |

P01.34 | Delay to enter sleep | 0–3600.0s | 0.0s |

P05.01–P05.06 | Digital input function selection | 1: Forward running 2: Reverse running 4: Forward jogging 5: Reverse jogging 6: Coast to stop 7: Fault reset 8: Running pause 21: Acceleration/deceleration time selection 1 22: Acceleration/deceleration time selection 2 30: Acceleration/deceleration disabled | / |

P08.06 | Running frequency of jog | 0.00Hz–P00.03 (max. output frequency) | 5.00Hz |

P08.07 | Acceleration time at jogging | 0.0–3600.0s | Depends on model |

P08.08 | Deceleration time at jogging | 0.0–3600.0s | Depends on model |

P08.00 | Acceleration time 2 | 0.0–3600.0s | Depends on model |

P08.01 | Declaration time 2 | 0.0–3600.0s | Depends on model |

P08.02 | Acceleration time 3 | 0.0–3600.0s | Depends on model |

P08.03 | Declaration time 3 | 0.0–3600.0s | Depends on model |

P08.04 | Acceleration time 4 | 0.0–3600.0s | Depends on model |

P08.05 | Declaration time 4 | 0.0–3600.0s | Depends on model |

P08.19 | Switching frequency of acceleration/deceleration time | 0.00–P00.03 (max. output frequency) 0.00Hz: No switch over If the running frequency is larger than P08.19, switch to acceleration /deceleration time 2 | 0 |

P08.21 | Reference frequency of acceleration/deceleration time | 0: Max. output frequency 1: Set frequency 2: 100Hz Note: Valid for straight-line acceleration/deceleration only | 0 |

P08.28 | Automatic fault reset times | 0–10 | 0 |

P08.29 | Automatic fault reset time interval | 0.1–3600.0s | 1.0s |

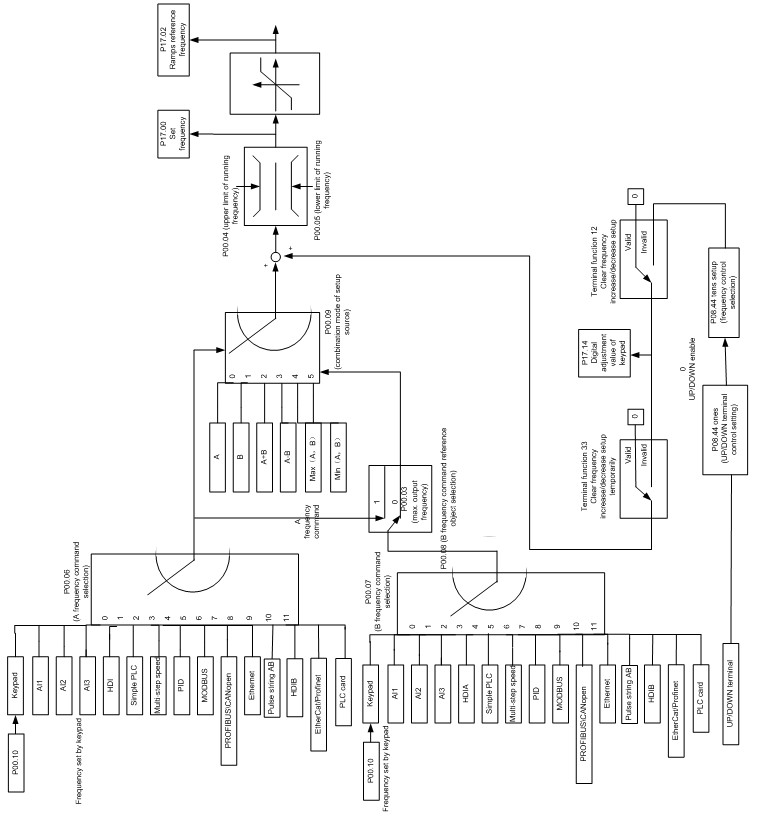

5.5.8 Frequency setup

The GD350 IP54 series VFD supports multiple kinds of frequency reference modes, which can be categorized into two types: main reference channel and auxiliary reference channel.

There are two main reference channels, namely frequency reference channel A and frequency reference channel B. These two channels support simple arithmetical operation between each other, and they can be switched dynamically by setting multi-function terminals.

There is one input mode for auxiliary reference channel, namely terminal UP/DOWN switch input. By setting function codes, users can enable the corresponding reference mode and the impact made on the VFD frequency reference by this reference mode.

The actual reference of VFD is comprised of the main reference channel and auxiliary reference channel.

The GD350 IP54 series VFD supports switch-over between different reference channels, and the rules for channel switch-over are shown below.

Present reference channel P00.09 | Multi-function terminal function 13 Channel A switches to channel B | Multi-function terminal function 14 Combination setup switches to channel A | Multi-function terminal function 15 Combination setup switches to channel B |

A | B | / | / |

B | A | / | / |

A+B | / | A | B |

A-B | / | A | B |

Max (A, B) | / | A | B |

Min (A, B) | / | A | B |

Note: "/" indicates this multi-function terminal is invalid under present reference channel.

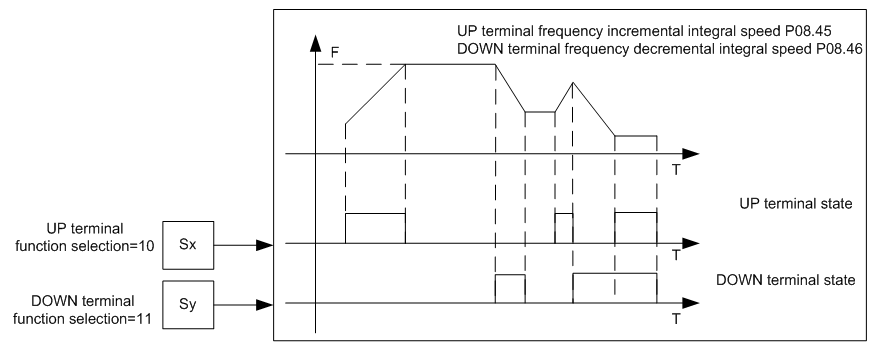

When setting the auxiliary frequency inside the VFD via multi-function terminal UP (10) and DOWN (11), users can increase/decrease the frequency quickly by setting P08.45 (UP terminal frequency incremental change rate) and P08.46 (DOWN terminal frequency decremental change rate).

Related parameter list:

Function code | Name | Detailed parameter description | Default value |

P00.03 | Max. output frequency | P00.04–400.00Hz | 50.00Hz |

P00.04 | Upper limit of running frequency | P00.05–P00.03 | 50.00Hz |

P00.05 | Lower limit of running frequency | 0.00Hz–P00.04 | 0.00Hz |

P00.06 | A frequency command selection | 0: Set via keypad 1: Set via AI1 2: Set via AI2 3: Set via AI3 4: Set via high speed pulse HDIA 5: Set via simple PLC program 6: Set via multi-step speed running 7: Set via PID control 8: Set via Modbus communication 9: Set via PROFIBUS/CANopen/DeviceNet communication 10: Set via Ethernet communication 11: Set via high speed pulse HDIB 12: Set via pulse string AB 13: Set via EtherCAT/PROFINET communication 14: Set via PLC card 15: Reserved | 0 |

P00.07 | B frequency command selection | 15 | |

P00.08 | Reference object of B frequency command | 0: Max. output frequency 1: A frequency command | 0 |

P00.09 | Combination mode of setup source | 0: A 1: B 2: (A+B) 3: (A-B) 4: Max (A, B) 5: Min (A, B) | 0 |

P05.01–P05.06 | Function of multi-function digital input terminal (S1–S4, HDIA, HDIB) | 10: Frequency increase (UP) 11: Frequency decrease (DOWN) 12: Clear frequency increase/decrease setting 13: Switch-over between setup A and setup B 14: Switch-over between combination setup and setup A 15: Switch-over between combination setup and setup B | / |

P08.42 | Reserved variables | / | / |

P08.43 | Reserved variables | / | / |

P08.44 | UP/DOWN terminal control | 0x000–0x221 Ones: Frequency enabling selection 0: UP/DOWN terminal setting is valid 1: UP/DOWN terminal setting is invalid Tens: Frequency control selection 0: Valid only when P00.06=0 or P00.07=0 1: Valid for all frequency modes 2: Invalid for multi-step speed when multi-step speed takes priority Hundreds: Action selection at stop 0: Valid 1: Valid during running, clear after stop 2: Valid during running, clear after receiving stop command | 0x000 |

P08.45 | UP terminal frequency incremental change rate | 0.01–50.00 Hz/s | 0.50 Hz/s |

P08.46 | DOWN terminal frequency decremental change rate | 0.01–50.00 Hz/s | 0.50 Hz/s |

P17.00 | Set frequency | 0.00Hz–P00.03 (max. output frequency) | 0.00Hz |

P17.02 | Ramps reference frequency | 0.00Hz–P00.03 (max. output frequency) | 0.00Hz |

P17.14 | Digital adjustment value | 0.00Hz–P00.03 | 0.00Hz |

5.5.9 Analog input

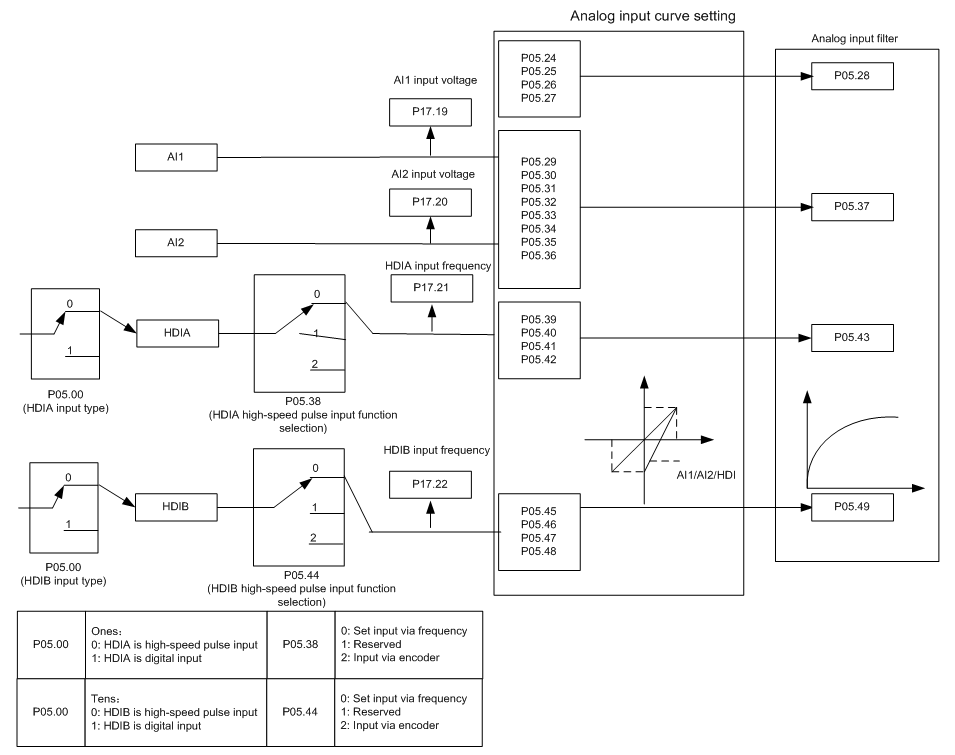

GD350 IP54 series VFD carries two analog input terminals (AI1 is 0–10V/0–20mA (voltage input or current input can be set by P05.50); AI2 is -10–10V) and two high-speed pulse input terminals. Each input can be filtered separately, and the corresponding reference curve can be set by adjusting the reference corresponds to the max. value and min. value.

Related parameter list:

Function code | Name | Detailed parameter description | Default value |

P05.00 | HDI input type | 0x00–0x11 Ones: HDIA input type 0: HDIA is high-speed pulse input 1: HDIA is digital input Tens: HDIB input type 0: HDIB is high-speed pulse input 1: HDIB is digital input | 0x00 |

P05.24 | Lower limit value of AI1 | 0.00V–P05.26 | 0.00V |

P05.25 | Corresponding setting of lower limit of AI1 | -300.0%–300.0% | 0.0% |

P05.26 | Upper limit value of AI1 | P05.24–10.00V | 10.00V |

P05.27 | Corresponding setting of upper limit of AI1 | -300.0%–300.0% | 100.0% |

P05.28 | Input filter time of AI1 | 0.000s–10.000s | 0.100s |

P05.29 | Lower limit value of AI2 | -10.00V–P05.31 | -10.00V |

P05.30 | Corresponding setting of lower limit of AI2 | -300.0%–300.0% | -100.0% |

P05.31 | Intermediate value 1 of AI2 | P05.29–P05.33 | 0.00V |

P05.32 | Corresponding setting of intermediate value 1 of AI2 | -300.0%–300.0% | 0.0% |

P05.33 | Intermediate value 2 of AI2 | P05.31–P05.35 | 0.00V |

P05.34 | Corresponding setting of intermediate value 2 of AI2 | -300.0%–300.0% | 0.0% |

P05.35 | Upper limit value of AI2 | P05.33–10.00V | 10.00V |

P05.36 | Corresponding setting of upper limit of AI2 | -300.0%–300.0% | 100.0% |

P05.37 | Input filter time of AI2 | 0.000s–10.000s | 0.100s |

P05.38 | HDIA high-speed pulse input function | 0: Set input via frequency 1: Reserved 2: Input via encoder, used in combination with HDIB | 0 |

P05.39 | Lower limit frequency of HDIA | 0.000 kHz – P05.41 | 0.000kHz |

P05.40 | Corresponding setting of lower limit frequency of HDIA | -300.0%–300.0% | 0.0% |

P05.41 | Upper limit frequency of HDIA | P05.39 –50.000kHz | 50.000kHz |

P05.42 | Corresponding setting of upper limit frequency of HDIA | -300.0%–300.0% | 100.0% |

P05.43 | HDIA frequency input filter time | 0.000s–10.000s | 0.030s |

P05.44 | HDIB high-speed pulse input function selection | 0: Set input via frequency 1: Reserved 2: Input via encoder, used in combination with HDIA | 0 |

P05.45 | Lower limit frequency of HDIB | 0.000 kHz – P05.47 | 0.000kHz |

P05.46 | Corresponding setting of lower limit frequency of HDIB | -300.0%–300.0% | 0.0% |

P05.47 | Upper limit frequency of HDIB | P05.45 –50.000kHz | 50.000kHz |

P05.48 | Corresponding setting of upper limit frequency of HDIB | -300.0%–300.0% | 100.0% |

P05.49 | HDIB frequency input filter time | 0.000s–10.000s | 0.030s |

P05.50 | AI1 input signal type | 0–1 0: Voltage type 1: Current type | 0 |

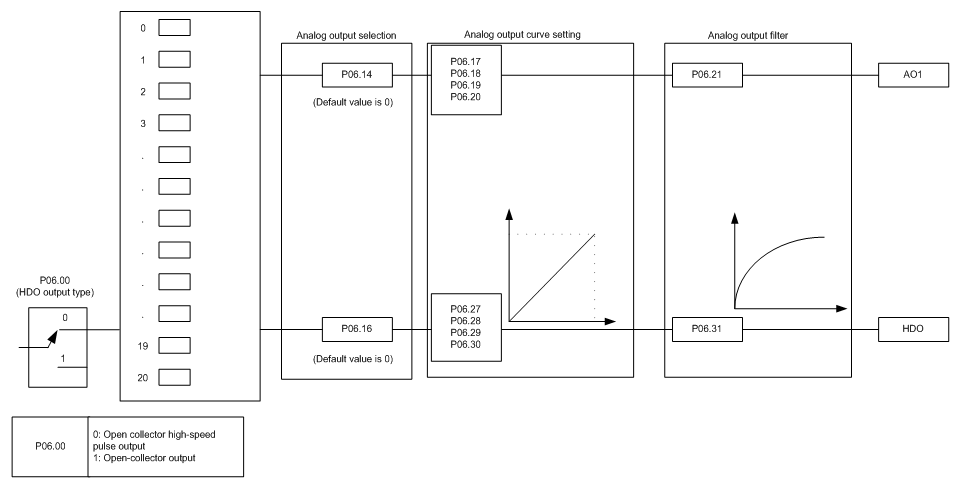

5.5.10 Analog output

The GD350 IP54 series VFD carries one analog output terminal (0–10V/0–20mA) and one high-speed pulse output terminal. Analog output signals can be filtered separately, and the proportional relation can be adjusted by setting the max. value, min. value, and the percentage of their corresponding output. Analog output signal can output motor speed, output frequency, output current, motor torque and motor power at a certain proportion.

AO output relationship description:

(The min. value and max. value of the output correspond to 0.% and 100.00% of the pulse or analog default output. The actual output voltage or pulse frequency corresponds to the actual percentage, which can be through function codes.)

Set value | Function | Description |

0 | Running frequency | 0–Max. output frequency |

1 | Set frequency | 0–Max. output frequency |

2 | Ramps reference frequency | 0–Max. output frequency |

3 | Running speed | 0–Synchronous speed corresponding to max. output frequency |

4 | Output current (relative to VFD) | 0–Two times of rated current of VFD |

5 | Output current (relative to motor) | 0–Two times of rated current of motor |

6 | Output voltage | 0–1.5 times of rated voltage of VFD |

7 | Output power | 0–Two times of rated power of motor |

8 | Set torque value | 0–Twice the motor rated current. A negative value corresponds to 0.0% by default. |

9 | Output torque | 0 – +/-(Twice the motor rated torque) |

10 | AI1 input value | 0–10V/0–20mA |

11 | AI2 input value | 0V–10V. A negative value corresponds to 0.0% by default. |

12 | AI3 input value | 0–10V/0–20mA |

13 | Input value of high-speed pulse HDIA | 0.00–50.00kHz |

14 | Set value 1 of Modbus communication | -1000–1000 |

15 | Set value 2 of Modbus communication | -1000–1000 |

16 | Set value 1 of PROFIBUS/CANopen/DeviceNet communication | -1000–1000 |

17 | Set value 2 of PROFIBUS/CANopen/DeviceNet communication | -1000–1000 |

18 | Set value 1 of Ethernet communication | -1000–1000 |

19 | Set value 2 of Ethernet communication | -1000–1000 |

20 | Input value of high-speed pulse HDIB | 0.00–50.00kHz |

21 | Set value 1 of EtherCAT/PROFINET communication | 0–1000. A negative value corresponds to 0.0% by default. |

22 | Torque current (bipolar) | 0–Triple the motor rated current. A negative value corresponds to 0.0% by default. |

23 | Exciting current | 0–Triple the motor rated current. A negative value corresponds to 0.0% by default. |

24 | Set frequency (bipolar) | 0–Max. output frequency. A negative value corresponds to 0.0% by default. |

25 | Ramp reference frequency (bipolar) | 0–Max. output frequency. A negative value corresponds to 0.0% by default. |

26 | Running speed (bipolar) | 0–Synchronous speed corresponding to max. output frequency. A negative value corresponds to 0.0% by default. |

27 | Set value 2 of EtherCAT/PROFINET communication | 0–1000 |

28 | C_AO1 from PLC | 0–1000 |

29 | C_AO2 from PLC | 0–1000 |

30 | Running speed | 0–Twice the motor rated synchronous speed. |

31 | Output torque (bipolar) | 0–Twice the motor rated torque. A negative value corresponds to 0.0% by default. |

32–47 | Reserved |

Related parameter list:

Function code | Name | Detailed parameter description | Default value | |

P06.00 | HDO output type | 0: Open collector high-speed pulse output 1: Open collector output | 0 | |

P06.14 | AO1 output selection | 0: Running frequency (0–Max. output frequency) 1: Set frequency (0–Max. output frequency) 2: Ramp reference frequency (0–Max. output frequency) 3: Rotational speed (0–Speed corresponding to max. output frequency) 4: Output current (0–Twice the VFD rated current) 5: Output current (0–Twice the motor rated current) 6: Output voltage (0–1.5 times the VFD rated voltage) 7: Output power (0–Twice the motor rated power) 8: Set torque (0–Twice the motor rated current) 9: Output torque (Absolute value, 0–+/- Twice the motor rated torque) 10: AI1 input (0–10V/0–20mA) 11: AI2 input (0–10V) 12: AI3 input (0–10V/0–20mA) 13: HDIA input(0.00–50.00kHz) 14: Value 1 set through Modbus (0–1000) 15: Value 2 set through Modbus (0–1000) 16: Value 1 set through PROFIBUS/CANopen/DeviceNet (0–1000) 17: Value 2 set through PROFIBUS/CANopen/DeviceNet (0–1000) 18: Value 1 set through Ethernet 1 (0–1000) 19: Value 2 set through Ethernet 2 (0–1000) 20: HDIB input (0.00–50.00kHz) 21: Value 1 set through EtherCAT/Profinet/EtherNetIP (0–1000) 22: Torque current (bipolar, 0–Triple the motor rated current) 23: Exciting current (bipolar, 0–Triple the motor rated current) 24: Set frequency (bipolar, 0–Max. output frequency) 25: Ramp reference frequency (bipolar, 0–Max. output frequency) 26: Rotational speed (bipolar, 0–Speed corresponding to max. output frequency) 27: Value 2 set through EtherCAT/Profinet/EtherNetIP (0–1000) 28: C_AO1 (Set P27.00 to 1. 0–1000) 29: C_AO2 (Set P27.00 to 1. 0–1000) 30: Rotational speed (0–Twice the motor rated synchronous speed) 31: Output torque (Actual value, 0–Twice the motor rated torque) 32–47: ReservedEtherCATEtherCAT | 0 | |

P06.15 | Reserved | 0 | ||

P06.16 | HDO high-speed pulse output | 0 | ||

P06.17 | Lower limit of AO1 output | -300.0%–P06.19 | 0.0% | |

P06.18 | Corresponding AO1 output of lower limit | 0.00V–10.00V | 0.00V | |

P06.19 | Upper limit of AO1 output | P06.17–300.0% | 100.0% | |

P06.20 | Corresponding AO1 output of upper limit | 0.00V–10.00V | 10.00V | |

P06.21 | AO1 output filter time | 0.000s–10.000s | 0.000s | |

P06.22– P06.26 | Reserved variable | 0–65535 | 0 | |

P06.27 | Lower limit of HDO output | -300.0%–P06.29 | 0.0% | |

P06.28 | Corresponding HDO output of lower limit | 0.00–50.00kHz | 0.0kHz | |

P06.29 | Upper limit of HDO output | P06.27–300.0% | 100.0% | |

P06.30 | Corresponding HDO output of upper limit | 0.00–50.00kHz | 50.00kHz | |

P06.31 | HDO output filter time | 0.000s–10.000s | 0.000s | |